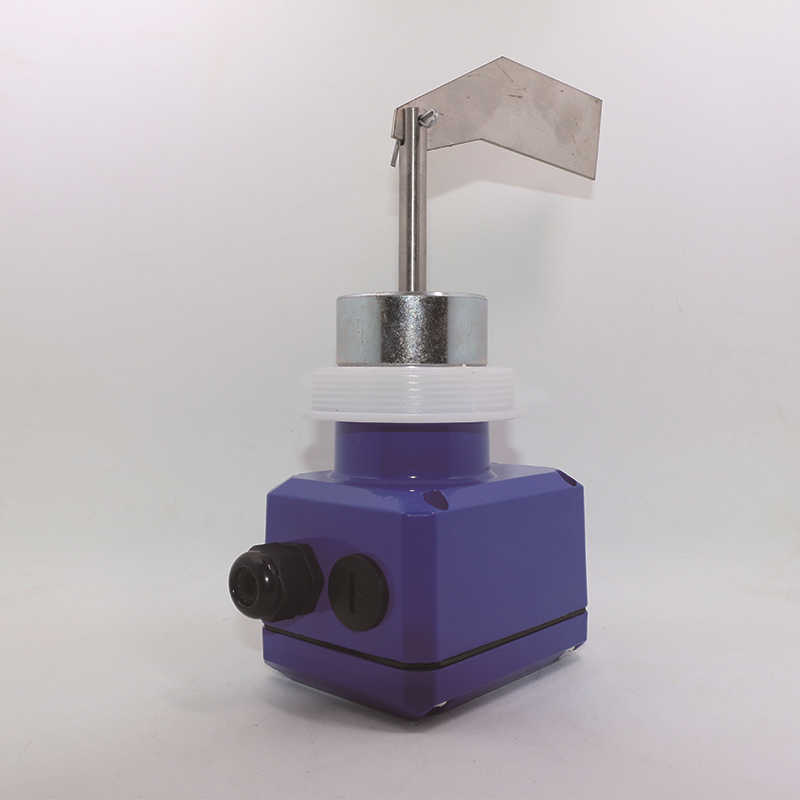

Anti rotation switch

The anti rotation switch is driven by a high-performance micro motor to rotate the guide shaft and measuring blades at a speed of 2.5/3R.PM. When the material reaches the set position on the silo, the blades are blocked, and the conduction mechanism is blocked. The rotation and displacement trigger switch sends a material signal, and the conversion switch is powered off, causing the internal electrical machine to stop running. When the material reaches the set position on the silo

- ZXKG-100

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

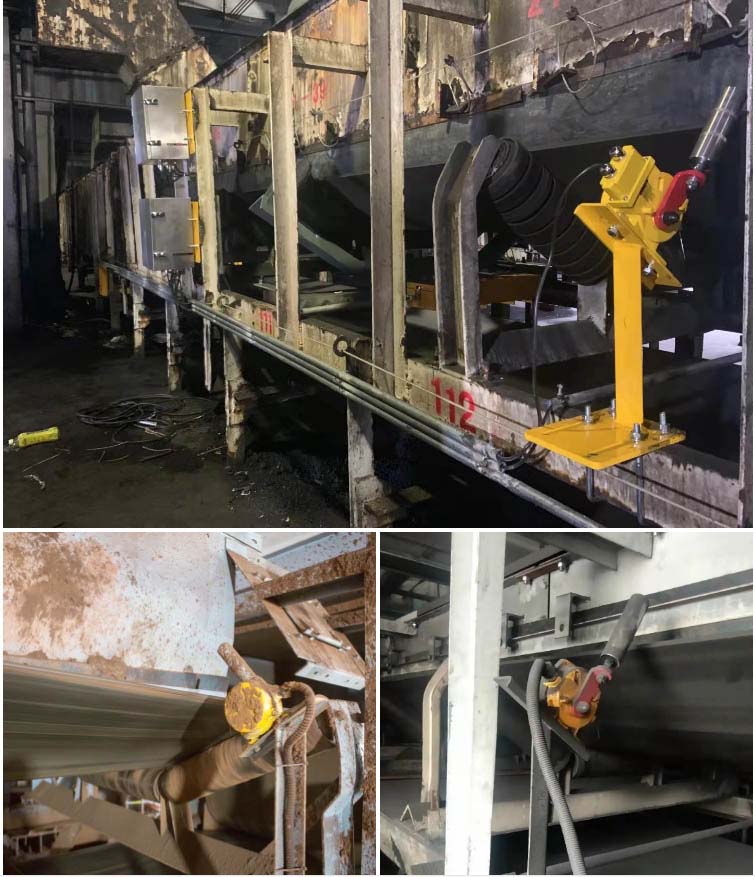

- The anti rotation switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical industry, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacker/reclaimer conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, etc.

Description

Resistance rotary switch ZXKG-100

Application fields of ZXKG-100 rotary switch:< Br/>

Used for measuring and controlling the upper and lower limits of powder, particle, or block material silos at normal temperature and pressure in industrial automation production and storage. It is widely used in the production and storage processes of industries such as steel, cement, power plants, feed, chemical plastics, chemical fertilizers, building materials, casting, mining, metallurgy, coal, and grain. Especially in the application of limit warning for conductive materials, frequent changes in material properties (state, humidity, dielectric constant, density, etc.), and large dust materials, it performs well and can be used for monitoring the height of solid materials. It has been widely used in monitoring the level of cement silos, coal silos, dust silos, ash silos, and other materials< Br/>

The storage position detection and control device used for detecting solid particles and powders in open containers is designed with advantages such as reasonable structure, technology, reliable performance, convenient use and maintenance, and anti bonding. It is only one-third of the imported brand products of the same model. This product has the following structural characteristics:< Br/>

1. The main exposed components are made of stainless steel and aluminum alloy, which have the characteristics of corrosion resistance, no pollution, moisture-proof, dustproof, etc. They can be used in harsh environments such as food equipment dust removal< Br/>

2. A mechanical overload protection device is adopted to avoid damage to the motor and deceleration caused by improper use or abnormal external forces& Nbsp< Br/>

3. The imported motor has reliable performance& Nbsp< Br/>

4. Double sealed bearings can ensure long-term continuous operation& Nbsp< Br/>

5. The oil seal design can prevent dust from infiltrating along the shaft, and the torque of the anti rotation switch is stable and reliable, and the torque size can be adjusted& Nbsp< Br/>

When the blades of the rotary switch are subjected to excessive loads, the motor rotation mechanism will automatically slip to protect it from damage& Nbsp< Br/>

7. To adapt to the different densities of various materials, users can choose the on/off switch and specifications for detecting blades. For the convenience of users, the movement is also equipped with a five speed sensitivity adjustment device& Nbsp< Br/>

8. The switch adopts a heat dissipation device, so it can be used in≤ Used in a material environment of 300 ℃ (which is currently beyond the capabilities of some capacitors, tuning forks, and level detection devices)& Nbsp< Br/>

Working principle:< Br/>

The ZXKG-100 rotary switch is driven by a high-performance micro motor to rotate the guide shaft and measuring blades at a speed of 2.5/3R.PM. When the material reaches the set position on the silo, the blades are blocked, and the conductive mechanism rotates and shifts to trigger the switch to send a material signal. At the same time, the conversion switch is powered off, and the internal motor stops running. When the material falls to the blade and loses obstruction, the conductive mechanism automatically returns to its position, the conversion switch is powered on, the motor works, and a no material signal is issued& Nbsp< Br/>

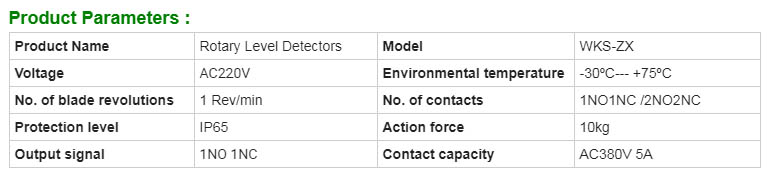

Technical parameters:< Br/>

1. Power supply: 220VAC/110VAC/24VAC 50Hz/60Hz< Br/>

2. Power: 3W< Br/>

3. Contact capacity: 8A/250VAC SPT< Br/>

4. Working temperature: -10~80 ℃ (specially customized up to 400 ℃, original imported up to 1000 ℃)< Br/>

5. Blade speed: 2.5/3R. PM< Br/>

6. Rotating torque: 1N. m< Br/>

7. Applicable material weight:≥ 0.4g/cm3< Br/>

8. Protection level: IP65< Br/>

9. Blade material: SUS304< Br/>

10. Outgoing port: M20× 1.5< Br/>

Advantages of Type:< Br/>

1. The measurement and control of material level in the warehouse is stable and accurate& Nbsp< Br/>

2. Strong anti-interference ability, instant use: Due to the absence of complex electronic components and amplification circuit parts inside, it is not affected by any electromagnetic wave interference, and can be used for a long time without any debugging and maintenance after installation& Nbsp< Br/>

3. Super strong anti shake performance design: It will not emit error signals even during material flow& Nbsp< Br/>

4. Material level display function: Adopting a long-life and high brightness indicator light, the material level display is intuitive and convenient& Nbsp< Br/>

5. Dual protection function: Overload protection function prevents the blades from being damaged by excessive external forces on the motor; The automatic protection function prevents the material level from working when the rotation of the material blades in the silo is obstructed, protecting the motor and extending its service life& Nbsp< Br/>

6. Excellent measurement reproducibility and environmental adaptability: not affected by changes in material particle size, shape, specific gravity, medium, wall scale, adhesion, temperature, humidity, dust concentration, etc& Nbsp< Br/>

7. Super strong dustproof sealing performance, even at a pressure of 1MPa, dust cannot enter& Nbsp< Br/>

8. Seismic resistance and anti loosening structure design to prevent component loosening and slipping; Using stainless steel material, it has excellent corrosion resistance and wear resistance& Nbsp< Br/>

9. Low, cost-effective& Nbsp< Br/>

Installation location and precautions< Br/>

1. When installing, it is necessary to consider the changes in the corner position of the material inside the warehouse& Nbsp< Br/>

Figure 3 Installation Instructions< Br/>

a. 1 and 2 did not select models based on the angle relationship between the static and dynamic states of the materials& Nbsp< Br/>

b. The inlet of 3 and 5 should be facing downwards& Nbsp< Br/>

c. 3, 4, and 5 horizontal measurement and control are not equipped with protective plates& Nbsp< Br/>

d. The 4 blades should not be in a vertical position at the feeding port& Nbsp< Br/>

2. Avoid the impact of adding materials and try to avoid areas with prolonged vibration& Nbsp< Br/>

3. The material full limit should be installed at a location where all remaining materials enter the warehouse after the feeding machine is stopped and there will be no overflow of materials& Nbsp< Br/>

4. The material empty limit should be installed at the position where the feeding machine starts to operate after the material empty signal is issued, and the time required to transport materials into the warehouse is calculated& Nbsp< Br/>

5. Due to the flow of materials and the operating environment, sometimes there may be a misalignment signal of full and empty materials (which usually does not occur). To ensure the correct signal is sent out, it is recommended that users install a delay measurement and control circuit (about 10 seconds)< Br/>

Our company produces ALN-111-2 dust removal cylinder specific level meter, BR-10A090 anti rotation level meter, C181-3 anti rotation level switch, BL08-100 series RF admittance level switch, CCL-1000 hopper RF admittance level meter, ES1000-156-E12-1Z RF admittance level switch, FTL50H liquid tuning fork switch, HQLWJ-1 anti explosion level meter IP66, HQZS-W anti rotation level meter level switch, HT-HL600 anti rotation level switch, HT-SCSG series tuning fork level switch, H-ZXK anti rotation level switch, JYBMW-A electrode level switch Type coal level control instrument material level, K-KZXK-123C18W18 type resistance rotation material level, L2000S-24VC RF admittance material level switch, RF18000 sintering ash removal hopper material level meter, RP-30 standard high temperature flange resistance rotation material level switch, RZ31BB0150 resistance rotation material level switch, SA100-XXX-S16 RF admittance material level switch, SF-3000 RF admittance material level switch, SPB2000 RF admittance material level switch material level switch, SR40F resistance rotation material level switch durable, SR-UZ-A material level switch, TXC1-2RJ resistance rotation material level switch, UHZ-A -51-J acid and alkali resistant liquid level sensor, UQK-02-B explosion-proof floating ball liquid level controller, UYZ-50002 capacitive level gauge material level gauge, floating ball liquid level switch TEK-1 anti-corrosion, RD-30 steel wire type anti rotation level switch, ZHSP56-VAPF1A1000MM high-temperature ash hopper level gauge, SH-38 special anti rotation level switch for mixing station, durable OLI-WOLONG level indicator ILTCO, strong anti-interference ability CLW-R-6 RF lock-in level gauge, adjustable anti rotation level switch PRL-100EBPRL-100E, radar level gauge 7ML5221-1EF, level switch ?Welcome to purchase!

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)