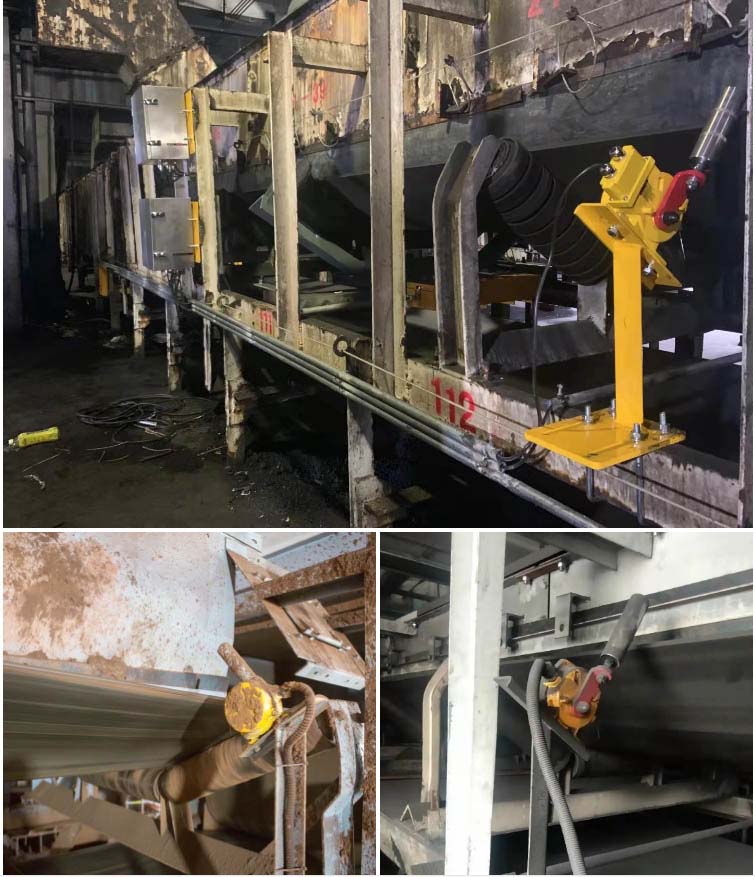

Bidirectional balance rope switch

The bidirectional rope switch is mainly composed of components such as a pull rod, cam, reset handle, lock groove, and micro switch. The pull rope switch is installed on both sides of the frame of the belt conveyor, and is connected by a steel wire rope along both sides of the conveyor equipment. In the event of an emergency in the conveyor belt equipment, pulling the steel wire rope at any point along the conveyor will pull the drive arm to start rotating, and through the transmission shaft, drive the torque spring to cause the cam to shift, driving the bidirectional rope switch to cut off the control line, causing the conveyor to quickly stop running.

- HFKLT2-I-Z

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- The bidirectional balance rope switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical industry, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other conveyors. {$InfoTitle}

Description

HFKLT2-I-Z bidirectional balanced rope switch

The HFKLT2-I-Z bidirectional balance rope switch is mainly composed of components such as a pull rod, cam, reset handle, lock groove, and micro switch. The pull rope switch is installed on both sides of the frame of the belt conveyor, and is connected by a steel wire rope along both sides of the conveyor equipment. In the event of an emergency in the conveyor belt equipment, pulling the steel wire rope at any point along the conveyor will pull the drive arm to start rotating, and through the transmission shaft, drive the torque spring to cause the cam to shift, driving the bidirectional rope switch to cut off the control line, causing the conveyor to quickly stop running< Br/>

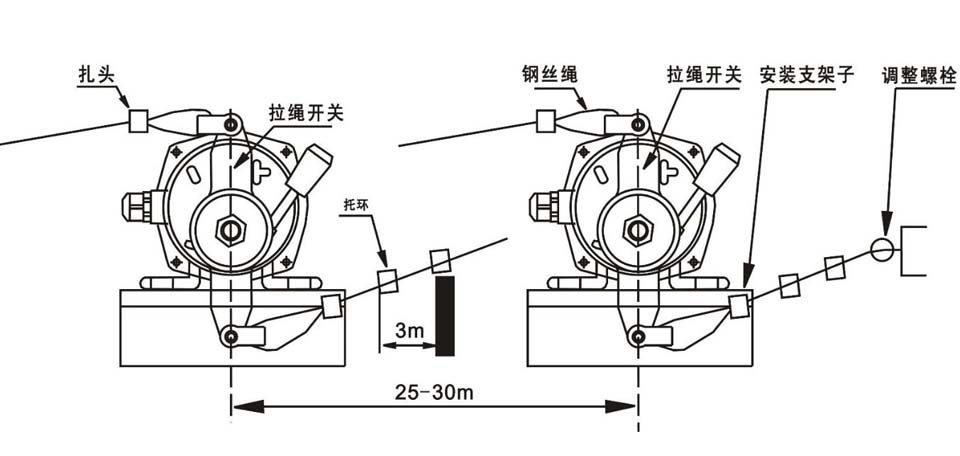

Installation and adjustment of bidirectional rope switch

Generally installed on two racks along the conveyor belt

1. Fix the rope switch on the bracket< Br/>

2. The distance between the two machines is 25-30m, using a diameter of Ф The 4mm steel wire rope connection should have moderate elasticity< Br/>

In order to reduce the impact of the weight of the steel wire rope on the switch and cause misoperation, a support ring is welded to the frame every 3 meters to support the steel wire rope and ensure its normal operation< Br/>

Installation precautions for HF-KLT2-I-Z bidirectional rope switch

1. The product casing is equipped with a grounding terminal, which ensures reliable grounding for users during installation and use< Br/>

2. There should be no toxic gases that corrode aluminum alloys on the installation site< Br/>

3. The maintenance of the product can only be carried out at the site or when it is confirmed that there is no combustible dust present on site< Br/>

Technical parameters:

Reset method: Type I automatic, Type II manual

Number of contacts: normally open, normally closed

Contact capacity:≤ AC380V 2A

Insulation voltage: AC1000V test for 1 minute

Number of output contacts: one open and one closed set of conversion contacts

Reliability: 10000 fault free operations

Weight: 2KG

Installation method

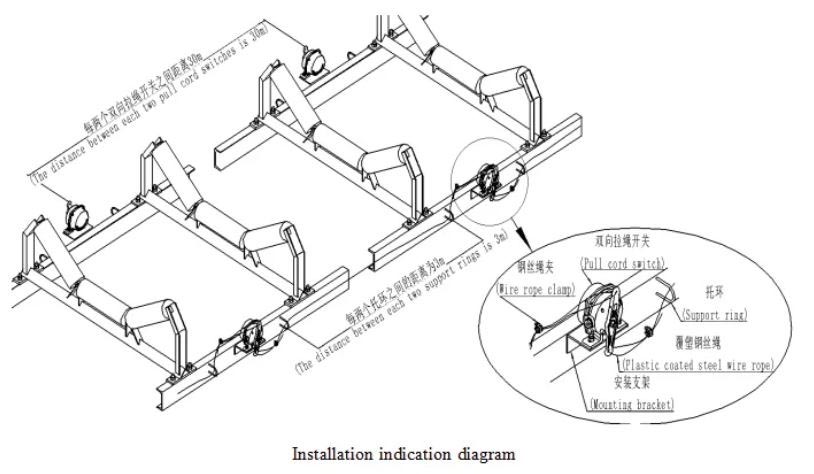

The bidirectional balance rope switch should be installed in a location with maintenance channels on both sides of the conveyor, and the installation position should ensure that maintenance personnel operate it in emergency situations

Convenient< Br/>

1. Fix the switch on the rack< Br/>

2. The distance between the two bidirectional rope switches on one side is about 50m, using a diameter ofΦ The steel wire rope connection of 4 should have moderate elasticity< Br/>

3. To reduce the impact of the weight of the steel wire rope on the start of the rope switch, a support ring is installed on the frame every 3 meters to support the steel wire rope< Br/>

4. The other end of the steel wire rope is tied to the tension spring (fixed with a rope buckle), and the two sides of the tension rope are tightened with a tightener without affecting normal use, ensuring that both sides

Balanced tension< Br/>

(Note: For the climbing section conveyor, the distance between the pull rope switches and the length of the pull rope should be minimized as much as possible.)

Our company produces AMT-K212LJ bidirectional rope switch, BFK-LC302 bidirectional rope switch [Emergency stop rope switch, BH-PW-LSKG JB-T bidirectional rope switch with LE light, BKLT-6100 explosion-proof bidirectional rope switch, BLKT2-1 automatic rope switch BLKT2-2 manual rope switch, BSFLS explosion-proof bidirectional rope switch, BX5800B bidirectional rope switch manual reset rope switch, BXYXL-II explosion-proof bidirectional rope switch, CPS-2 bidirectional rope switch, EBPC-20 bidirectional rope switch, ELAW-31W bidirectional rope switch, ELAW-61P rope switch ELAP-20 belt running] Partial switch, EXKLT2-2 explosion-proof bidirectional rope switch, EXKLT2-I, EXKLT2-II explosion-proof bidirectional rope switch, EXKLT2-W explosion-proof rope switch, FJK-W150 magnetic induction switch, FKB-II explosion-proof bidirectional rope switch, FKLT2-II rope switch, bidirectional rope switch, FKLT2 rope switch belt rope switch, FLK-1-3A-380 emergency stop button manual bidirectional rope switch, FLT2-II KC-S-D bidirectional rope switch with indicator light, optical display rope switch, KLSF-1 emergency button bidirectional rope switch, KLT2-1, KLT2-11 dust explosion-proof bidirectional rope switch, KLT2-I, KLT2-II bidirectional rope switch, KLT2-S2 rope switch, KSLFKT1-1 rope switch, LE indicator light BGX-K2LE rope switch, bidirectional rope switch, LK2-15B-H bidirectional rope switch, LK-11 belt rope switch, LK-IS bidirectional rope switch, LLJZS75-02WV rope switch, accident switch, LLP1-S explosion-proof bidirectional rope switch, LLP6A-L bidirectional rope switch, LSF-1 and LSF-2 stainless steel drawstring switches, LS-I and LS-II drawstring switches, LSKG-I and LSKG-II bidirectional drawstring switches, LSKT2-2 explosion-proof bidirectional drawstring switch, LXA-01GKH-T1-A stainless steel drawstring switch, LXA-01GKH-T2-C stainless steel bidirectional drawstring switch, WZHB-GKXJ-20 bidirectional drawstring switch, XLLS-J-I bidirectional drawstring switch, XT-A-F2GH bidirectional drawstring switch emergency stop switch, XTKS-20 bidirectional drawstring switch drawstring type emergency stop switch, YFBLKT2-I YFBLKT2-II bidirectional rope switch, YHL-11 corrosion-resistant bidirectional rope switch, intrinsic safety HRLS-S bidirectional rope switch, stainless steel rope switch XT-PLS-405, stainless steel rope switch HQLX-1736GKKT1, stainless steel bidirectional rope switch HQLA-R0320ZMLY, stainless steel HQL52996MPC304 bidirectional rope switch, stainless steel rope switch HQLX-1736GKKT1, stainless steel rope switch, rope switch HQLS-LXB316, stainless steel bidirectional rope switch HQLA-R0320ZMLY, Stainless steel bidirectional rope switch SBNPB-T2 IP67, strong anti-interference LXA-01GKH-T2-G bidirectional balanced rope switch, rope switch JSBKLS-II 10-year technical rope switch, corrosion-resistant NTZH-9SXL11BF bidirectional rope switch, high-temperature resistant LXA-34T2KK bidirectional rope switch and other electrical products. The specifications and models are complete and the price is reasonable. Welcome to purchase!

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)