Bidirectional pull switch

The bidirectional pull switch is a bidirectional action, and pull ropes can be installed on both sides of the switch. When the belt conveyor equipment malfunctions, on-site workers pull the ropes on both sides of the bidirectional pull rope switch, causing the cam inside the switch to press the micro switch and put the switch into working mode, issuing a shutdown signal to prevent and control the equipment and personnel.

- HFKLT2-II

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

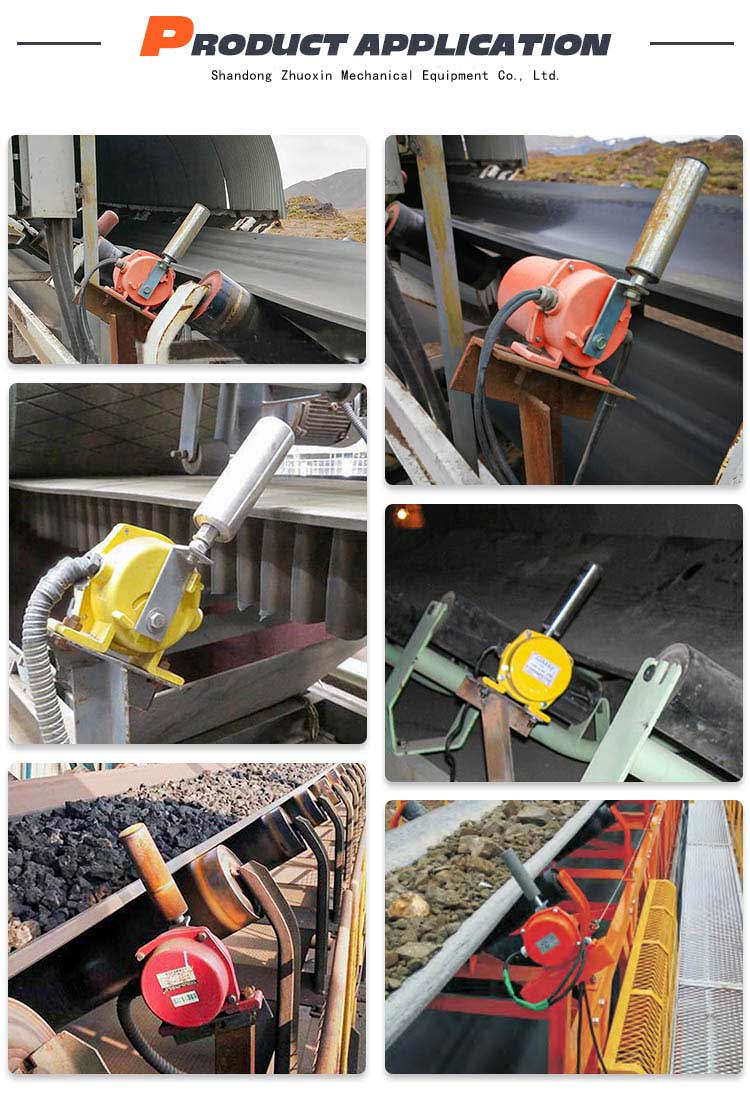

- The bidirectional pull switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical engineering, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors.

Description

Bidirectional pull switch HFKLT2-II

The bidirectional pull wire switch HFKLT2-II is a protective switch that achieves emergency shutdown of the system in the event of an accident during the operation of a tape conveyor, protecting personnel or equipment< Br/>

1、 Overview

The bidirectional pull switch HFKLT2-II (i.e. pull rope switch, emergency stop switch) adopts an integral seal, which has the characteristics of waterproof, moisture-proof, dustproof, etc., and is suitable for use in harsh indoor and outdoor environments with high humidity and dust< Br/>

2、 Main use

This series of products is a protective switch for emergency shutdown of the system in case of accidents during the operation of tape conveyors, protecting personnel or equipment< Br/>

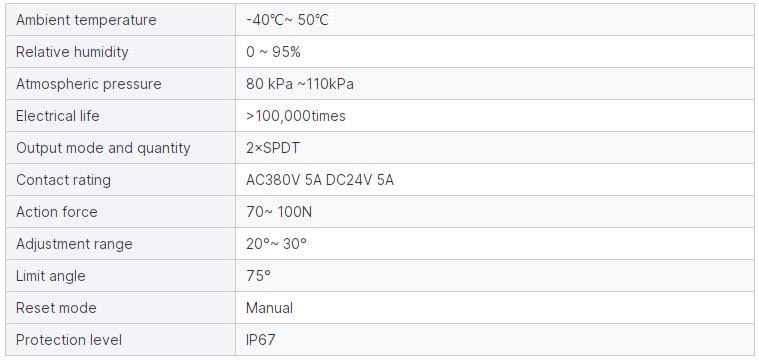

3、 Main technical indicators

Working voltage& Nbsp& Nbsp; AC220V

Action angle& Nbsp& Nbsp; 25< Br/>

Contact capacity& Nbsp& Nbsp; AC220V; 3A

Extreme angle& Nbsp& Nbsp; 75< Br/>

Contact form& Nbsp& Nbsp; Double breakpoint 1 normally open and 1 normally closed

Protection level& Nbsp& Nbsp; IP65

Service life& Nbsp& Nbsp; 100000 times

Re & Nbsp; Quantity& Nbsp& Nbsp; 2.5Kg

4、 External structure and working principle

1. Appearance structure

2. Working principle

This product is a bidirectional action, and pull ropes can be installed on both sides of the switch. When the belt conveyor equipment malfunctions, on-site workers pull the ropes on both sides of the bidirectional pull rope switch, causing the cam inside the switch to press the micro switch and put the switch into working mode, issuing a shutdown signal to prevent and control the equipment and personnel< Br/>

5、 Installation and wiring

(1) Installation

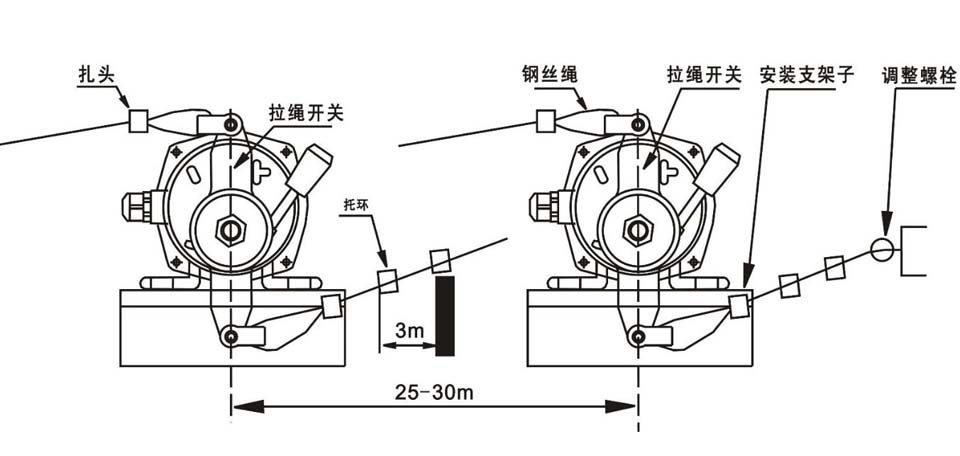

Users can create a self-made installation bracket based on the installation dimensions indicated by the external structure, or they can order it from our company. Fix the switches on both sides of the tape machine, install them in pairs, and meet the following requirements:

1. During installation, the product should be positioned below the tape (its height should be convenient for on-site personnel to use) and fixed on both sides of the tape conveyor along the line. The distance between each pull rope switch should be around 40 meters< Br/>

2. Tie the pull rope to the swing arm of the switch body, fix it with a rope clip, and first install support rings on both sides of the switch nearby. Then install support rings every 3 meters to avoid excessive deflection and ensure the normal use of the switch< Br/>

3. Under the premise of ensuring normal operation of the switch, try to tighten the ropes on both sides as much as possible and minimize the vertical deflection of the rope< Br/>

4. For slope tape machines, the length of the pulling rope and the switching distance should be shortened as appropriate< Br/>

(1) Wiring

Lead out a four core rubber sleeve cable at the outlet, which is red, blue, yellow, and black. Among them, red and blue are the outgoing lines of the dynamic break point. Yellow and black represent the outgoing lines of the dynamic closing contact. The wiring principle is shown in Figure (4)

6、 Maintenance and upkeep

1. Regular dust removal, regular inspection of switch contact conversion status to ensure normal operation< Br/>

2. If the machinery or steel wire rope is severely rusted, it should be replaced in a timely manner< Br/>

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)