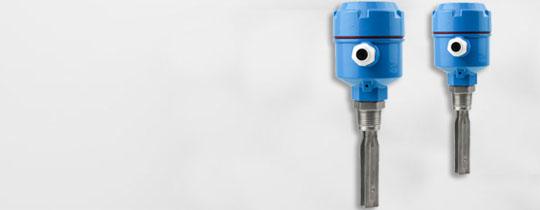

Chute blockage switch

The chute blockage switch is widely used to detect whether the chute in a belt conveyor system is blocked. If blockage occurs, this detector can send a fault alarm signal through the detection circuit connected to the machine, immediately stopping the belt conveyor to avoid the occurrence of conveyor system paralysis and equipment damage accidents caused by chute blockage.

- ZXLDM-X

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

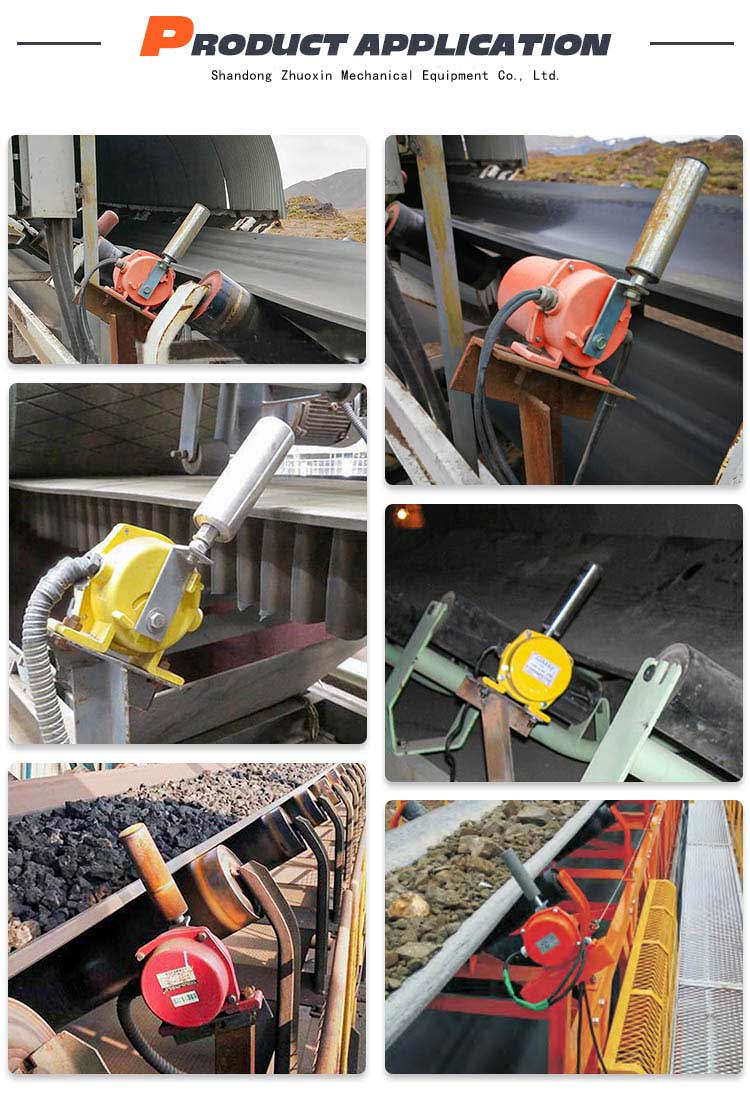

- Chute blockage switches are widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, and chemical engineering, including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors.

Description

Chute blockage switch and chute blockage detection device

Chute switches are widely used to detect blockages in the chutes of belt conveyor systems. If blockage occurs, this detector can send a fault alarm signal through the detection circuit connected to the machine, immediately stopping the belt conveyor to avoid the occurrence of conveyor system paralysis and equipment damage accidents caused by chute blockage< Br/>

The loading section of the conveyor is a location where damage to the conveyor belt often occurs, especially when equipped with a loading funnel, which is more likely to occur. This type of accident may be caused by the following reasons and situations:

Large pieces of material are fed into the funnel

Excessive material humidity

Subsequent conveyor belt slipping

Application Principles

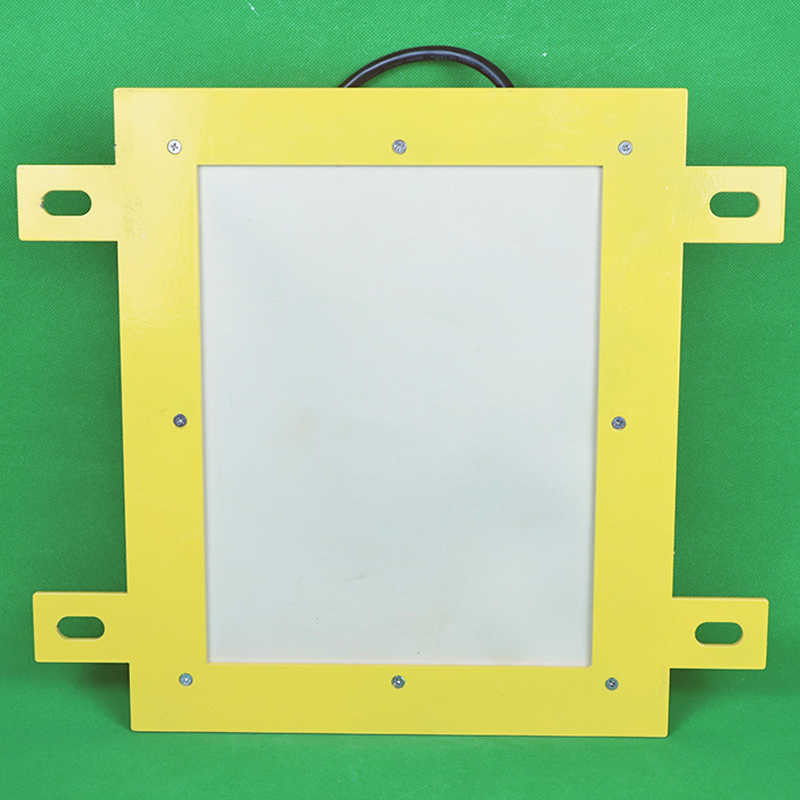

Composed of a detection board and a limit switch, it has a simple structure and quick response. When the chute is blocked, the detection board is squeezed by the material, tilts outward, triggers the limit switch, and sends a shutdown or alarm signal. After the chute is unobstructed, the switch will automatically reset& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp< Br/>

1. The sensitivity can be adjusted, and the detection sensitivity range at the front end of the detection board can reach 9.8~14.7N, which can detect small particles and blocky materials< Br/>

2. The plate type chute switch consists of a swinging detection plate and a limit switch, which can be installed on the side wall of the chute< Br/>

3. This detector adopts a side pressure movable door structure. After troubleshooting, the thrust of the pressure spring automatically resets the movable door< Br/>

4. Use dustproof bearings, which can be used in harsh environments with high dust levels< Br/>

5. Simple structure and easy installation< Br/>

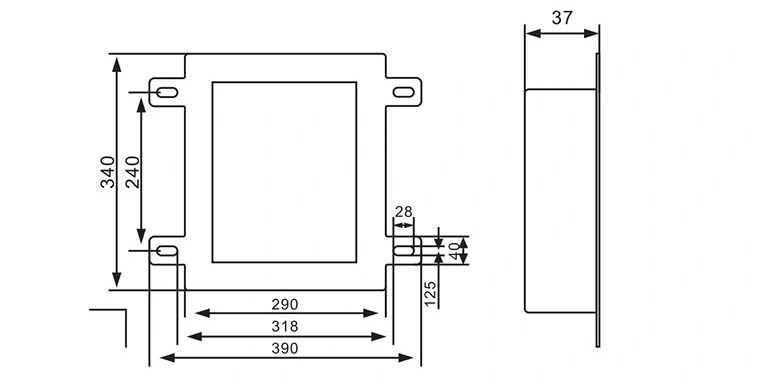

Type& Nbsp; Number: ZXLDM-X

Detection force: 9.8N~14.7N (detection board front section)

Protection level: IP55

Connect& Nbsp; Point: 1a+1b

Contact capacity: 250V AC; 5A

Quality& Nbsp; Quantity: 11kg

Reset type: automatic reset

Automatic reset: bidirectional action

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)