Explosion proof chute blockage detector

The explosion-proof chute blockage detector consists of a detection plate and a limit switch, with a simple structure and rapid response. When the chute is blocked, the detection board is squeezed by the material, tilts outward, triggers the limit switch, and sends a stop or signal. After the chute is cleared, the switch will automatically reset. Installed on the side wall of the chute parallel to the conveyor belt. Sensitivity can be adjusted, and the detection force at the front end of the detection board can be adjusted from 9.8 to 14.7N, which can detect small particles and blocky materials.

- XBW-220

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

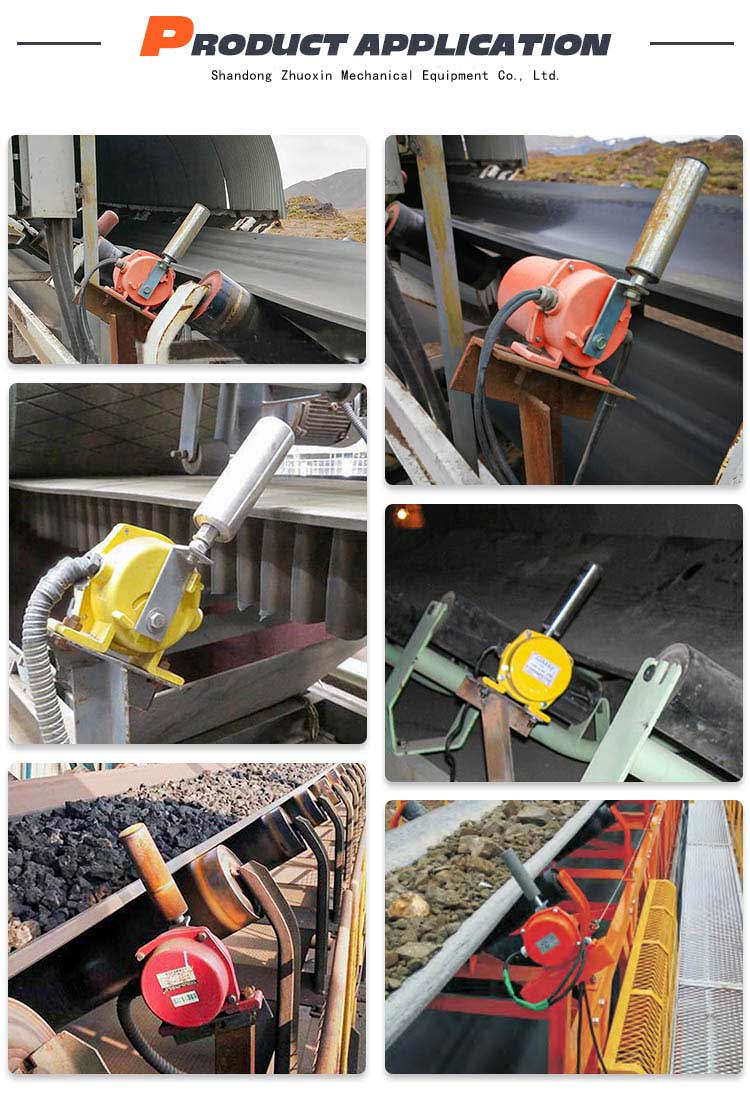

- Chute blockage detectors are widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, and chemical engineering, including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacker/reclaimer conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and more.

Description

Explosion proof chute blockage detector

XBW-220 explosion-proof chute blockage detector

The explosion-proof chute blockage detector consists of a detection plate and a limit switch, with a simple structure and rapid response. When the chute is blocked, the detection board is squeezed by the material, tilts outward, triggers the limit switch, and sends a stop or signal. After the chute is cleared, the switch will automatically reset. Installed on the side wall of the chute parallel to the conveyor belt. Sensitivity can be adjusted, and the detection force at the front end of the detection board can be adjusted from 9.8 to 14.7N, which can detect small particles and blocky materials< Br/>

Product Description:

This product is a level control instrument designed and produced on the basis of absorbing advanced technology and functions from similar foreign products. It consists of sensors, electronic measurement and control units, and a protective casing, using three-terminal co shieiD technology to completely eliminate sensor misoperation caused by factors such as hanging materials, temperature, pressure, and medium density, thereby improving the reliability of the product. It can be widely used in the fields of metallurgy, chemical industry, petroleum, electricity, food, papermaking, coal, building materials, medicine, etc. for material level and liquid level control, and can be used in conjunction with PLC programmable Kongzhiqi or Dcs distributed control systems to achieve automatic control and automatic detection of the production process< Br/>

Technical parameters:

Environmental conditions for use

Environmental temperature: -20 ℃ -+40 ℃

The relative temperature should not exceed 85%

Action angle: 5°< Br/>

Extreme angle: 10°< Br/>

Number of contacts: 1 normally open, 1 normally closed

Customizable according to customer needs

Contact capacity: 24-380V AC/DC

Current I: 5 A

Reliability:>1000000

Protection level: IP65

Weight: 5KG

Installation and use:

Installed on the vertical side wall of the chute that is not directly impacted by materials

The product can be divided into two types: Type I and Type II, and the installation height is determined according to user needs. Generally, it is recommended to install it at the bottom of the chute and two-thirds of the height upwards< Br/>

This machine can also be used in four parts and two groups. One group is installed on the side wall of the chute at a relative height of one-third from the bottom, as a light blockage detection device. It is used for the vibration device to send a signal. When the chute is blocked, the vibration device receives the signal and starts to vibrate. The other group is installed at two-thirds of the bottom as a heavy blockage, and outputs a shutdown signal when a blockage occurs< Br/>

Our company produces BLC-II chute blockage switch, CCS-1011 chute blockage switch, E502-3300-026 coal blockage switch, ELPP-22EX chute blockage switch, EXLM-S explosion-proof chute blockage switch, GU-330-belt conveyor coal stacking protection sensor, HLM-KH-B chute blockage switch, HQM series chute blockage switch, LK-1 chute blockage switch, LLS-I, LLS-1 chute blockage switch, LM-G chute blockage switch, chute blockage, LM-X chute blockage, LM-Y coal blockage switch protection level EXI, LM-Y chute blockage protection device, SMY-C-F1 coal blockage switch, TS-1 chute blockage switch, blockage switch, explosion-proof blockage switch TS-01-EX IP55, A08-6B8A-561 coal conveying blockage switch for thermal power plants, two open and two closed SO2-W chute blockage, chute blockage switch XT-P86 C24V explosion-proof type, chute blockage detection device WDML&flash; F65600G, Chute Three Prevention Automatic Processing System Coal Blocking Switch, KBJ-220Y-II Explosion proof Coal Stacking Sensor for Coal Mine Conveyors, SMG-A-2 Explosion proof Chute Blocking Switch for Coal Mine, YHLJ-II Chute Blocking Switch for Belt Blocking, Universal Anti Blocking Switch Device NS-T-304-25 Material Blocking Switch, and other various specifications and models of Chute Blocking Switch. The product specifications are complete and the price is reasonable. Welcome to purchase!

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)