Explosion proof longitudinal tear switch

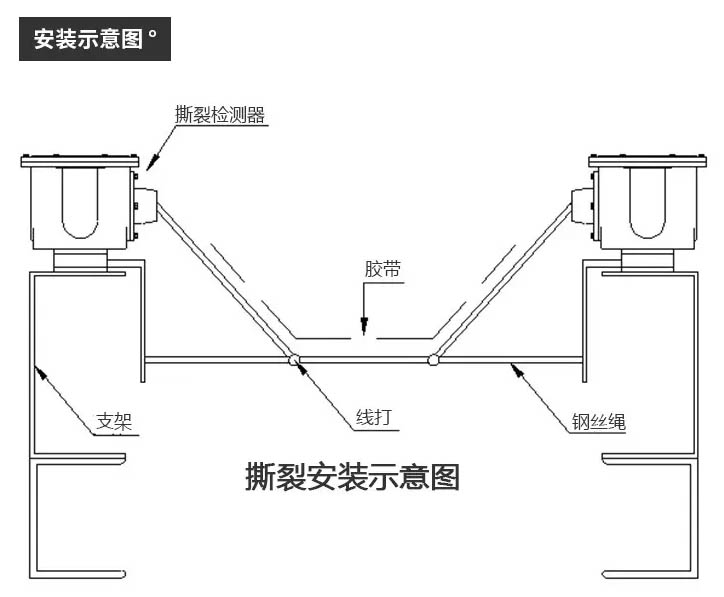

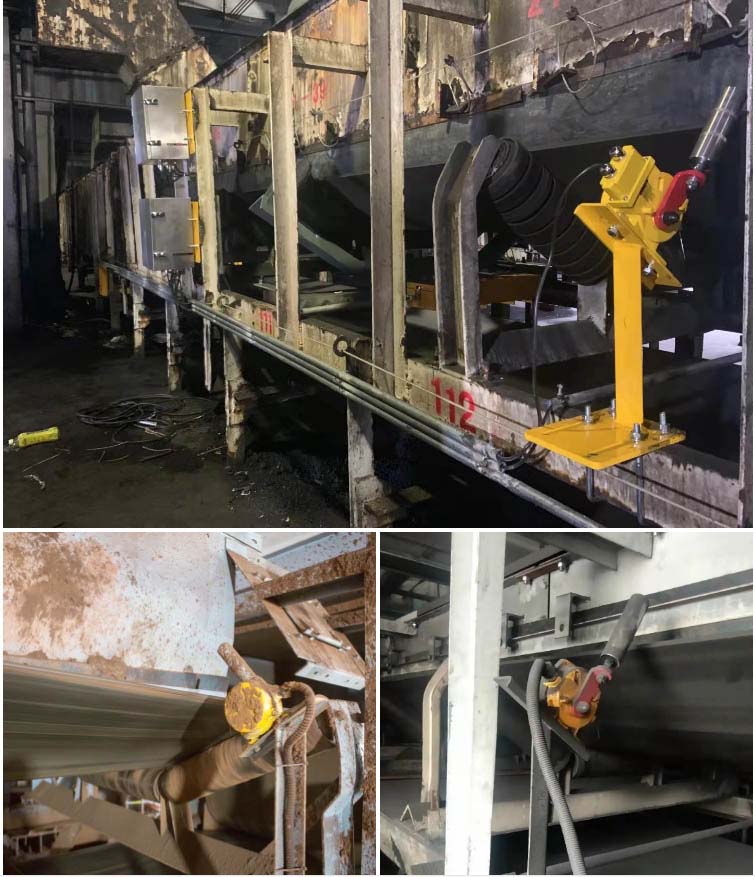

Explosion proof longitudinal tear switches are installed in pairs on both sides of the conveyor belt, connected by two segments of aviation steel wire ropes wrapped in ethylene. One end of the rope is fixed to the support bracket, and the other end is connected to the pull ring of the tear switch. A closed circuit is formed by two sections of wire rope in the lower part of the belt. When an object or torn belt is suspended and one or two wires are swept down, a fault is detected. Due to the force acting on the wire rope, it pulls out the pull ring shaft outward but causes the self locking handle to bounce upwards. At this time, the two micro switches inside the machine issue a warning or turn off the conveyor. After troubleshooting, press down on the self selling handle to reset the camshaft inside the machine and wait for the machine to start.

- EXZL-K

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- Explosion proof longitudinal tear switches are widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, and chemical engineering, including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacker/reclaimer conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other conveyors.

Description

EXZL-K explosion-proof longitudinal tear switch

Advantages of EXZL-K explosion-proof longitudinal tear switch design:

1. Simple and sturdy structure, no maintenance required. 2. Cast aluminum shell with protective layer. 3. Integrated cover plate for easy wiring. 4. Large capacity micro contacts.

Working principle of EXZL-K explosion-proof longitudinal tear switch:

Paired installation on both sides of the conveyor belt, connected by two segments of aviation steel wire ropes wrapped in ethylene. One end of the rope is fixed to the support bracket, and the other end is connected to the pull ring of the tear switch. A closed circuit is formed by two sections of wire rope in the lower part of the belt. When an object or torn belt is suspended and one or two wires are swept down, a fault is detected. Due to the force acting on the wire rope, it pulls out the pull ring shaft outward but causes the self locking handle to bounce upwards. At this time, the two micro switches inside the machine issue a warning or turn off the conveyor. After troubleshooting, press down on the self selling handle to reset the camshaft inside the machine and wait for the machine to start< Br/>

Instructions for use:

1. The tear switch is set between the buffer rollers under the receiving section tape< Br/>

2. Press the installation bracket and tear switch, and the pull ring of the tear switch should be at the same height as the edge of the tape. If the height is not enough, a shim or channel steel can be added under the bracket. After measuring the height, weld the bracket and support firmly< Br/>

3. Hang a rope: One end passes through the pull ring of the tear switch and is secured with a rope, while the other end passes through the circular hole in the middle of the tear switch bracket of the other end and is ready for use< Br/>

4. Install two tear switches and hang two cables. Buckle the two ropes together at an additional 30 degree bend, but do not buckle them tightly to move< Br/>

5. Tighten the restraining rope in the middle hole of both brackets and then fasten the rope buckle< Br/>

6. The tightness of the rope: It is generally recommended to trigger the switch when it is applied at 0.9kg< Br/>

7. When the load sinks, the tape should be kept at a distance of 5mm-10mm from the cable< Br/>

Equipment data:

Reset method: manual reset

Dynamic stroke: 20mm

Extreme travel: 25mm

Number of contacts: 2

Action force: 5kg

Contact capacity: AC380V/

Protection level: IP65

Reliability:> 100000 times

Environmental temperature: -30 ℃~+60 ℃< Br/>

Relative humidity: not greater than 85

Our company produces AEVC-12C tear detection switches, BZL-220B, BZL-K220 longitudinal tear switches, tear switches, CD-100 longitudinal tear switches, EXZL-K explosion-proof longitudinal tear switches, HFZL-K longitudinal tear switches, HQSL-20GSK belt longitudinal tear protection device, HQZS-2030PTG-C tear sensor, JCSL-I longitudinal tear switch, belt tear detection device, JYBGZL-Z-A photoelectric detection longitudinal tear protection device, KBZL-220 explosion-proof longitudinal tear switch, PLR50 belt tear protection switch, QZSL-I longitudinal tear, SL-A and SL-B belt longitudinal tear switches, SL-I belt anti tear switch, longitudinal tear switch, SLKG-115-2 longitudinal tear switch, SLKG-200HL longitudinal tear switch, THZL-B-II FSZL longitudinal tear, belt anti tear switch SCPT-200-35, belt anti tear switch SLKQ-KB6, belt longitudinal tear switch BZL-A-I, Fully enclosed HRSLB-20Y longitudinal tear switch, tear converter SCPT-220-35, tear switch SLKQ-J02 belt longitudinal tear protection device, original longitudinal tear LN-K1G2EA4-BF3, longitudinal tear sensor ZX-ZSE-10 explosion-proof type, longitudinal tear detection sensor IPTHSL-L, longitudinal tear switch GHSK-3365F, longitudinal tear switch HQSL-02GKH-A, longitudinal tear switch JSBMTZS, longitudinal tear switch TL-B, Various specifications and models of longitudinal tear switches such as YHZL-1 are available, with complete product specifications and reasonable prices. Welcome to purchase!

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)