Explosion proof slip switch

The slip switch is horizontally installed on the conveyor bracket between the up and down tapes, creating a certain pressure on the surface of the tape to prevent accidental action caused by wheel jumping. The speed detector can operate without the need for a power supply. When the operating speed of the tape machine is lower than the set value of this product, the relay of the detector will output a control signal, and the speed can be adjusted arbitrarily.

- EXDH-III

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- Slippery switches are widely used in various fields such as metallurgy, coal, cement building materials, mining, electricity, ports, metallurgy, chemical engineering, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors.

Description

The slip switch is used to prevent the belt conveyor from slipping (stalling) with the active drum during operation. It can prevent serious accidents caused by slipping. This machine can also be used for chain starting and stopping of multiple belt conveyors, low-speed brake or frying protection, making on-site operation simple and improving safety. Belt conveyors have been widely used in industries such as steel, electricity, coal mines, and ports< Br/>

Working principle:

The slip switch is horizontally installed on the conveyor bracket between the up and down tapes, creating a certain pressure on the surface of the tape to prevent accidental action caused by wheel jumping. The speed detector can operate without the need for a power supply. When the operating speed of the tape machine is lower than the set value of this product, the relay of the detector will output a control signal, and the speed can be adjusted arbitrarily< Br/>

Structural features:

The slip switch consists of a relay, connecting shaft, contact wheel, support arm, and other structures< Br/>

Easy to install and safe to use. Due to being installed on top of the return tape, the entire machine runs smoothly and avoids damage to the tape when the teacher malfunctions at the debris< Br/>

The shell is made of aluminum alloy casting, and the surface is coated with electrostatic spray coating technology, with a uniform paint film and strong adhesion. The overall protection level of the machine is relatively high, suitable for working under harsh conditions< Br/>

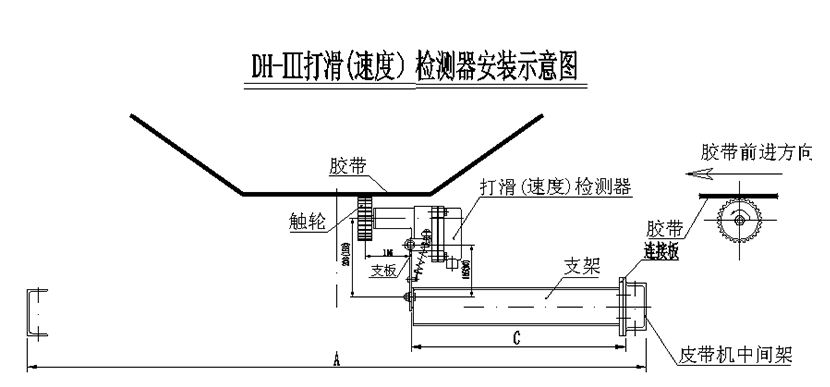

Usage and installation:

First, weld the fixed bracket onto the crossbeam of the conveyor; Then connect the support arm to the bracket with a pin shaft and a split pin< Br/>

After installation, the following requirements should be met:

The slip detection device prevents the tape from running in the same direction, with a contact distance of 200-300mm from the edge of the tape

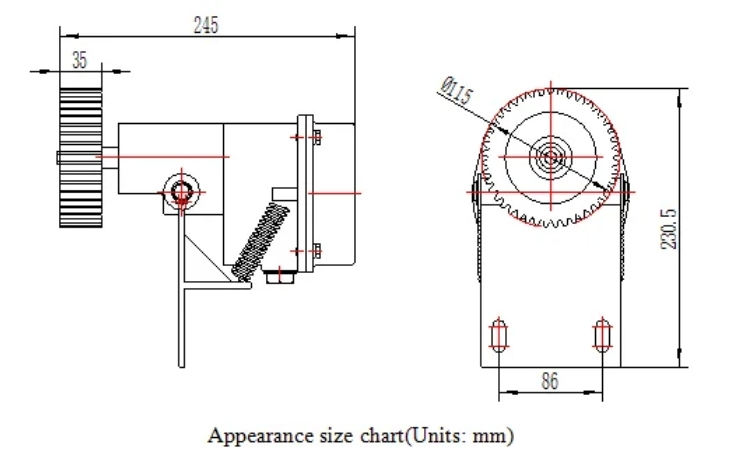

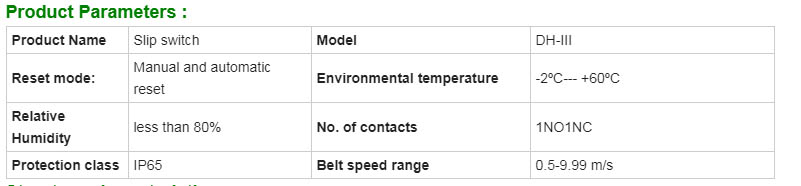

Technical parameters:

Environmental conditions for use

Environmental temperature: -5° C -+40° C< Br/>

Relative temperature: not exceeding 85% RH (at 25 ° C)

Main technical parameters

Number of solution points: Normally open: 1 Normally closed: 1

Applicable belt speed: 1.0-5.0m/s

Output method: With a load capacity of AC380V2A or DC12-50V, as the output is a solid-state relay,

When purchasing, it should be indicated that it is used for DC or AC conditions. 2A (suitable for resistive or inductive)

Protection level: IP55 Weight: 4.5kg

Wiring method:

When this machine leaves the factory, it is equipped with a 1.0 meter long cable, and the wiring method refers to the color indicated on the label< Br/>

Our company produces BLC-II chute blockage switch, CCS-1011 chute blockage switch, E502-3300-026 coal blockage switch, ELPP-22EX chute blockage switch, EXLM-S explosion-proof chute blockage switch, GU-330-belt conveyor coal stacking protection sensor, HLM-KH-B chute blockage switch, HQM series chute blockage switch, LK-1 chute blockage switch, LLS-I, LLS-1 chute blockage switch, LM-G chute blockage switch, chute blockage, LM-X chute blockage, LM-Y coal blockage switch protection level EXI, LM-Y chute blockage protection device, SMY-C-F1 coal blockage switch, TS-1 chute blockage switch, blockage switch, explosion-proof blockage switch TS-01-EX IP55, A08-6B8A-561 coal conveying blockage switch for thermal power plants, two open and two closed SO2-W chute blockage, chute blockage switch XT-P86 C24V explosion-proof type, chute blockage detection device WDML&flash; F65600G, Chute Three Prevention Automatic Processing System Coal Blocking Switch, KBJ-220Y-II Explosion proof Coal Stacking Sensor for Coal Mine Conveyors, SMG-A-2 Explosion proof Chute Blocking Switch for Coal Mine, YHLJ-II Chute Blocking Switch for Belt Blocking, Universal Anti Blocking Switch Device NS-T-304-25 Material Blocking Switch, and other various specifications and models of Chute Blocking Switch. The product specifications are complete and the price is reasonable. Welcome to purchase!

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)