Slipping switch

The slip switch is used to detect the slip between the tape and the active cylinder of the belt conveyor during operation, preventing serious accidents caused by slip. DH-III can also be used for interlocking start and stop of multiple tape conveyors, and low-speed brake protection.

- DH-III

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- Slippery switches are widely used in various fields such as metallurgy, coal, cement building materials, mining, electricity, ports, metallurgy, chemical engineering, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors.

Description

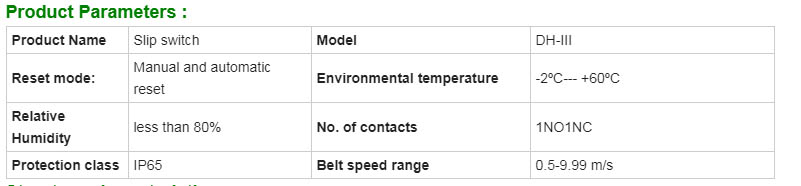

DH-III slip switch usage conditions and technical parameters

1. Altitude below 2000m< Br/>

2. Environmental temperature: -35 ℃ -+60 ℃

3. Relative humidity: not more than 95%

4. Atmospheric pressure: 80-110kPa

5. Protection level: IP67

6. Working position: Installed on the reversing drum or under the tape on the belt conveyor

7. During the starting or stopping process of the tape conveyor, the detector will automatically delay and the belt speed will start to detect normally< Br/>

8. Number of output contacts: One normally open and one normally closed set of conversion contacts

9. Action direction: bidirectional

The DH-III slip switch is suitable for detecting slippage between the tape and the active drum during the operation of belt conveyors, to prevent malignant accidents caused by slippage. Due to the use of computer chips and 8421 dial switches, the reliability and detection accuracy of the detector are greatly improved. Users can set their own speed requirements and achieve delayed or adaptive starting process, making the detector more stable and reliable< Br/>

Working principle of DH-III slip switch: The DH-III slip detector is in close contact with the adhesive tape through the contact wheel. When the contact wheel and the moving adhesive tape move at a linear speed, the internal detection sensor of this device is continuously blocked by an infrared light source, outputting a pulse signal, which is isolated by photoelectric and enters the counting unit, while also reflecting the actual tape speed. The motion information of the adhesive tape is input into the microcontroller pulse signal through an infrared photoelectric sensor. After receiving the information, the microcontroller performs calculation and judgment processing to monitor the stalling situation of the running adhesive tape. When the running adhesive tape speed is 25-30% lower than the normal speed, a switch signal is issued. Users can use this switch signal to achieve stalling and shutdown in their control network to prevent production accidents caused by adhesive tape slipping< Br/>

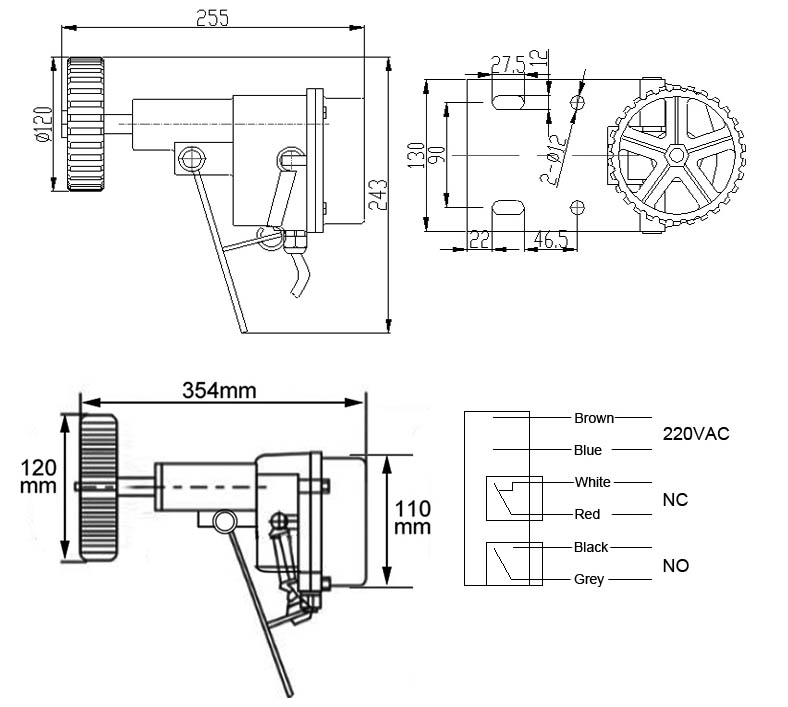

The DH-III slip switch setting device uses an 8421 dial switch to set preset speed values and slip limits. The overall structure can be installed at any position of the tape machine, with no wear on the contact wheel and tape, fast response speed, high accuracy, small error, and convenient installation and adjustment< Br/>

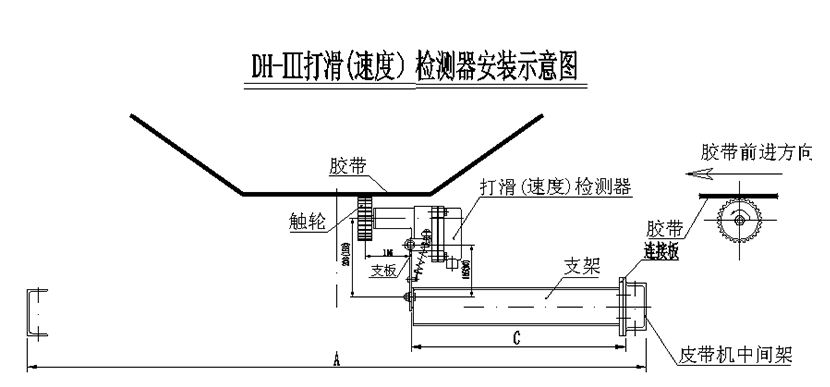

Installation method for DH-III slip switch< Br/>

1. When installing this device, it can be installed under the tape on the belt conveyor according to the following requirements and meet the on-site usage conditions. After installation, it should be ensured that the slip detector is parallel to the tape surface when the tape is loaded. At the same time, when the tape is running without material, the contact wheel of the detector and the tape surface should be reliably contacted, and the installation position should be ensured to be in the place with minimal vibration and tape shaking< Br/>

2. The installation should ensure that the axis of the contact wheel is parallel to the tape, and the direction of movement is parallel to the direction of tape operation< Br/>

3. Users can configure installation brackets according to the size and height of the tape machine. During installation, ensure that the contact wheel and tape surface are within the elastic range, that is, the bracket and tape surface are perpendicular. Please refer to the installation diagram for specific installation details< Br/>

Our company specializes in producing belt conveyor protection devices, mainly including EXLDM-X explosion-proof chute blockage detector, EXDH-III explosion-proof slip switch, EXKPT explosion-proof two-stage deviation switch, EXKLT2 explosion-proof bidirectional pull rope switch, KBZ-220 explosion-proof limit switch, ZL-B explosion-proof longitudinal tear protection Wait

DH03E-1-W, DH01E-1-W, DH02E-1-W, DH03E-1-TH, DH01E-1-TH, DH02E-1-TH, XT-SS-1D, XDH-HL, YHSJ-II, DH02E-1-WW, XTD-SH, JYB/RDC-B, KBJ-220Y, EXDH-III, FYDDH-02, YB RDC-C, DH-IV, SMS-PXK-BI, SMS-BI, slip switch, EXDH-III, explosion-proof slip switch, slip speed measuring device

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)