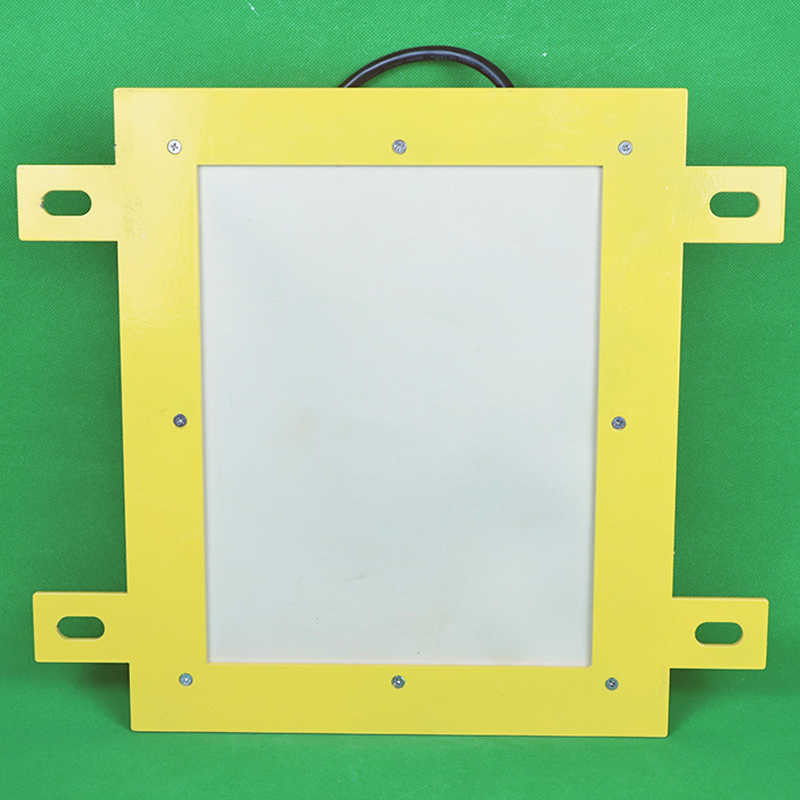

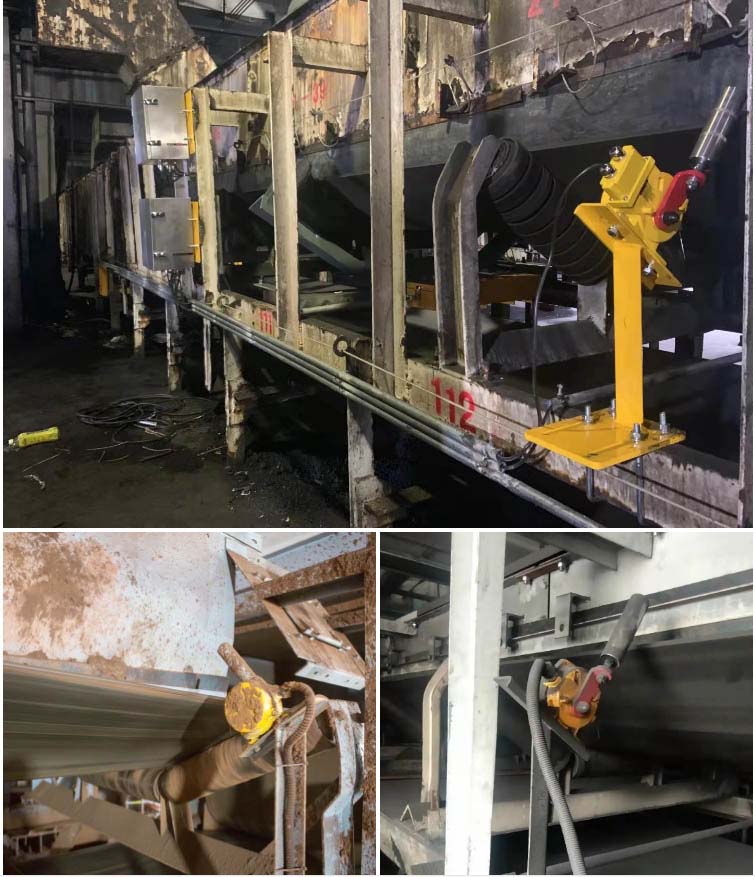

Square chute blockage switch

The square chute blockage switch adopts a gate structure, with a spring reset, and is installed on the side wall of the chute. When the material causes blockage in the chute, the accumulated material will definitely give pressure to the side wall of the chute, thereby pushing the movable door of this device inward. When the deflection angle of the movable door is greater than the controlled angle, its control switch will act, thereby issuing a warning or shutdown signal. If connected to the control circuit of the vibrator, it can achieve automatic vibration without stopping in case of mild blockage. After troubleshooting the blockage, the movable door will automatically reset.

- YHLJ-I

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- Chute blockage switches are widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, and chemical engineering, including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors.

Description

Square YHLJ-I chute blockage switch

This device adopts a gate structure, with spring reset, and is installed on the side wall of the chute. When the material causes blockage in the chute, the accumulated material will definitely give pressure to the side wall of the chute, thereby pushing the movable door of this device inward. When the deflection angle of the movable door is greater than the controlled angle, its control switch will act, thereby issuing a warning or shutdown signal. If connected to the control circuit of the vibrator, it can achieve automatic vibration without stopping in case of mild blockage. After troubleshooting the blockage, the movable door will automatically reset< Br/>

Product Description:

The device is installed on the side wall of the chute. When there is a blockage inside the chute, the accumulated material will inevitably squeeze the movable door and cause it to shift, activating the travel switch and issuing an alarm or shutdown signal. After troubleshooting, the movable door automatically resets under the action of the weight block< Br/>

Chute blockage is mainly used to prevent belt conveyor chute blockage. The product is suitable for industries such as coal mines, docks, power plants, building materials, chemicals, metallurgy, and grain storage, and is used for conveying bulk materials with belt conveyors< Br/>

Overview:

This is used for detecting blockages in the chute of the coal conveying system, and can provide warning or shutdown signals. It can also be connected to a vibration motor to troubleshoot blockages< Br/>

Structural features:

1. This adopts a side pressure movable door structure. After troubleshooting, the pressure of the weight block causes the valve to automatically reset< Br/>

2. Imported travel switches are used inside the machine, which are sensitive in action and highly reliable< Br/>

3. Small in size, easy to install< Br/>

Cast aluminum shell with anti-corrosion coating

Overloaded microswitch contacts

High sensitivity, with a force of only 0.9Kg to trigger the switch

The imported travel switch is used inside the machine, which is sensitive in action and has high reliability

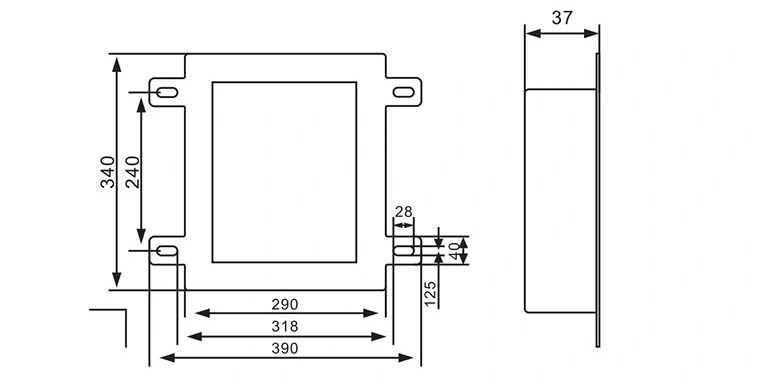

Technical parameters

Action angle 5;, Extreme angle 10°< Br/>

Contact capacity: 1A/125 (C),/250V or 380V (AC)< Br/>

The shell is dust-proof, corrosion-resistant, and rainproof. Protection level: IP67

Number of switches: 1 normally open or 1 normally closed (the number of switches can be increased according to user needs)

The switch can be connected in a normally open or normally closed form according to user needs< Br/>

Environmental temperature: -20--60 ℃

Chute blockage switch is a common phenomenon in the bulk material conveying system of belt conveyors. Therefore, it is often necessary to have on-site workers clear the chute after shutdown, which affects normal production, increases labor intensity of workers, and causes unnecessary economic losses< Br/>

Our company produces BLC-II chute blockage switch, CCS-1011 chute blockage switch, E502-3300-026 coal blockage switch, ELPP-22EX chute blockage switch, EXLM-S explosion-proof chute blockage switch, GU-330-belt conveyor coal stacking protection sensor, HLM-KH-B chute blockage switch, HQM series chute blockage switch, LK-1 chute blockage switch, LLS-I, LLS-1 chute blockage switch, LM-G chute blockage switch, chute blockage, LM-X chute blockage, LM-Y coal blockage switch protection level EXI, LM-Y chute blockage protection device, SMY-C-F1 coal blockage switch, TS-1 chute blockage switch, blockage switch, explosion-proof blockage switch TS-01-EX IP55, A08-6B8A-561 coal conveying blockage switch for thermal power plants, two open and two closed SO2-W chute blockage, chute blockage switch XT-P86 C24V explosion-proof type, chute blockage detection device WDML&flash; F65600G, Chute Three Prevention Automatic Processing System Coal Blocking Switch, KBJ-220Y-II Explosion proof Coal Stacking Sensor for Coal Mine Conveyors, SMG-A-2 Explosion proof Chute Blocking Switch for Coal Mine, YHLJ-II Chute Blocking Switch for Belt Blocking, Universal Anti Blocking Switch Device NS-T-304-25 Material Blocking Switch, and other various specifications and models of Chute Blocking Switch. The product specifications are complete and the price is reasonable. Welcome to purchase!

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)