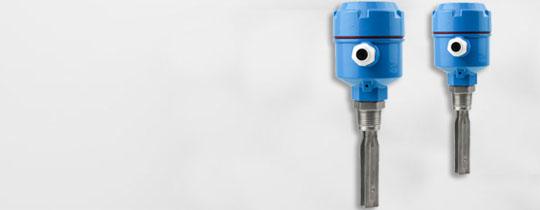

Explosion proof stainless steel two-stage deviation switch

The material of the stainless steel two-stage deviation switch is stainless steel. The deviation switch adopts the international L advanced double bearing structure design, and the transmission shaft is made of stainless steel material, which has stronger corrosion resistance. The reset rod is precision cast, sturdy and wear-resistant.

- EXZXPP-220LX

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

- The two-stage deviation switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical industry, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors. {$InfoTitle}

Description

Explosion proof stainless steel two-stage deviation switch EXZXPP-220LX

Explosion proof stainless steel two-stage deviation switch EXZXPP-220LX is a protective device installed on belts, tapes, and belt conveyors

The explosion-proof stainless steel two-stage deviation switch is a protective device installed on the belt, tape, and belt conveyor. When the deviation occurs during operation compared to the belt, tape, and belt conveyor, and the running simulation angle reaches the angle of this device, this switch can give a warning signal. When the deviation angle reaches the second level angle set by this switch, it can give a stop signal to the belt, tape, and belt conveyor that is in deviation operation, Stop the belt conveyor in abnormal operation. When the belt conveyor is adjusted to normal state by the staff, this protective device will immediately reset itself, giving a working signal to the stopped belt, tape, and belt conveyor. The belt conveyor will start working. This switch is easy to install and responds quickly. The working angle can be adjusted relative to the customer's actual usage situation, It is now widely used in various industries< Br/>

Technical parameters:

1. Rated voltage: AC380V

2. Rated current:

3. Number of contacts: Two sets of normally open and normally closed contacts

4. Shell protection level: T-shaped dustproof shell, protection level IP67

5. Surrounding environment temperature: -25~80 ℃

6. The switch can operate under vibration conditions with a frequency of 10-60Hz and an amplitude of 0.75mm (10g)

7. External dimensions: Shell L× W× H (mm) 190× 135× 100< Br/>

8. Operating force: 5-7 kg

Introduction to usage environment

Working temperature: -20 to 60 degrees Celsius. The ambient temperature can be customized according to customer requirements for processing products with high temperature resistance, corrosion resistance, low temperature resistance, explosion-proof, dust prevention, and other technical specifications< Br/>

Relative humidity: not greater than 85

Product Common Name: Two level deviation switch, correction switch, anti deviation switch, deviation

Installation instructions

1. Both sides of the base of the two-stage deviation switch have Ф 12mm hole, drilled on the iron frame next to the belt conveyor Ф 12mm hole, using M10× Tighten the deviation switch with 30mm screws< Br/>

2. The installation of the deviation switch should be carried out at a location where the conveying device is prone to deviation, referring to the process requirements of the application unit. At the same time, the distance and thrust between the belt and the gear wheel should be considered. It is recommended to install the distance between the belt and the gear wheel between 120-160mm

3. Installation distance: It is recommended to install a pair of deviation switches every 50 meters< Br/>

4. The deviation switch is equipped with a 0.5 meter long four core rubber sleeve cable when leaving the factory. The core wire is equipped with wire numbers 1, 2, 3, and 4, where 1 and 2 are normally open contacts for warning signals and 3 and 4 are normally closed contacts for secondary shutdown signals< Br/>

When installing and wiring the product, please follow the product manual and do not change the wiring method on your own< Br/>

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)