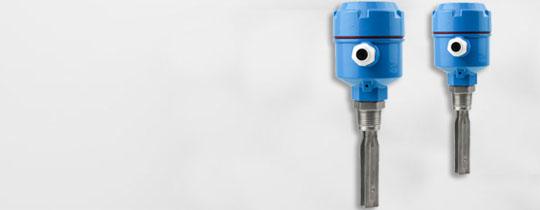

Explosion proof junction box two-stage deviation switch

The explosion-proof junction box two-stage deviation switch is also known as the anti deviation switch. Used to detect the deviation phenomenon during the operation of belt conveyors, and output warning or shutdown signals based on the actual deviation amount of the belt, which can prevent accidents caused by belt deviation.

- EXZXPP-220H

- ZHUOXIN

- 24V-380V

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

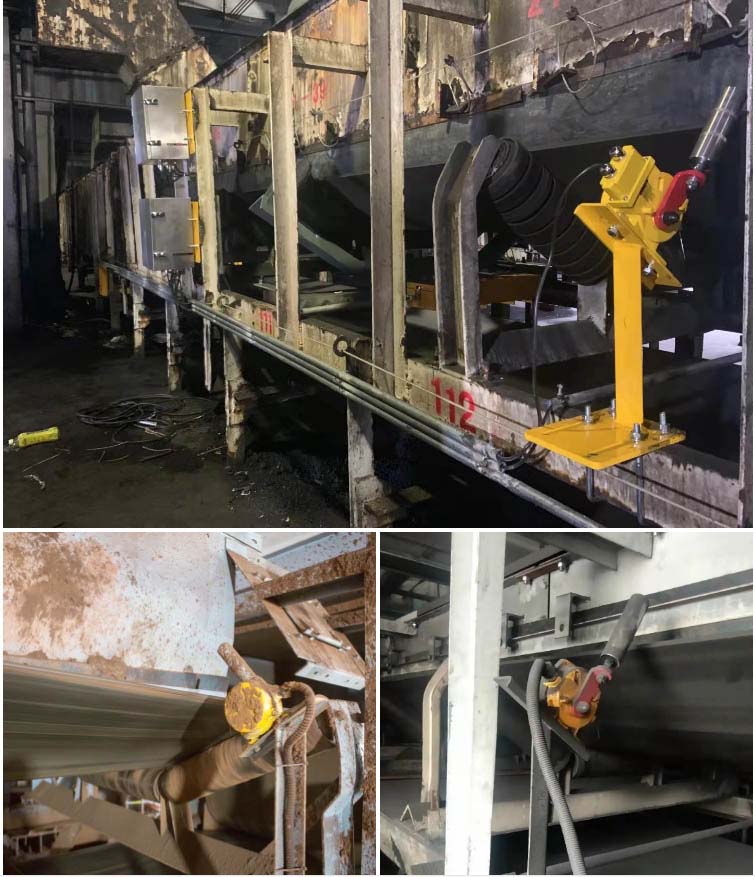

- The two-stage deviation switch is widely used in various fields such as metallurgy, coal, cement building materials, mining, power, ports, metallurgy, chemical industry, etc., including conventional belt conveyors, underground cable support belt conveyors, ship loading and unloading systems, stacking/reclaiming conveyors, inclined and shuttle conveyors, cranes, excavators, boom limiters, skirt feeders, and other types of conveyors. {$InfoTitle}

Description

Production of explosion-proof junction box deviation switches, production of belt conveyor series protection devices, two-stage deviation switches, bidirectional rope pulling switches, slip switches, tilt switches, chute blockage detection devices, anti rotation material level switches, speed sensors, chain breakage protection devices, speed switches, etc< Br/>

The explosion-proof junction box two-stage deviation switch is also known as the anti deviation switch. Used to detect the deviation phenomenon during the operation of belt conveyors, and output warning or shutdown signals based on the actual deviation amount of the belt, which can prevent accidents caused by belt deviation. This series of deviation switches has a two-stage action function. The action is used for warning, and the secondary action is used for automatic shutdown. When the tape machine is running, when the tape deviates and comes into contact with the vertical roller of this switch, the vertical roller rotates. If the deviation continues to increase, the squeezing vertical roller will shift& Nbsp< Br/>

When the deflection angle of the vertical roller exceeds 12? When the switch is activated, output (warning signal). When the deflection angle of the vertical roller exceeds 30? When the second level switch is activated, it outputs a shutdown signal< Br/>

Technical parameters of the built-in junction box rope switch

Parameters: Voltage: 220V/380V,

Current options: 2A, 3A, 4A, 6A, 7A, 8A, 9A, 10A. 1

The switch signal is used for warning. If this signal is connected to the running adjustment device, it can achieve automatic adjustment of running deviation without stopping the machine& Nbsp< Br/>

The second level switch signal is used for shutdown. Connect this signal to the control circuit to achieve automatic shutdown under severe deviation< Br/>

After troubleshooting, when the tape leaves the vertical roller for normal operation, the vertical roller can automatically reset& Nbsp< Br/>

In order to adapt to long-term use under outdoor conditions, this product is sealed as a whole, and the internal metal parts are galvanized and purified. The external parts, except for the shell, are coated with multiple layers of bright chrome. The shell is made of cast aluminum/stainless steel, and the surface is treated with electrostatic spraying technology, making it suitable for use in harsh environments< Br/>

Notes

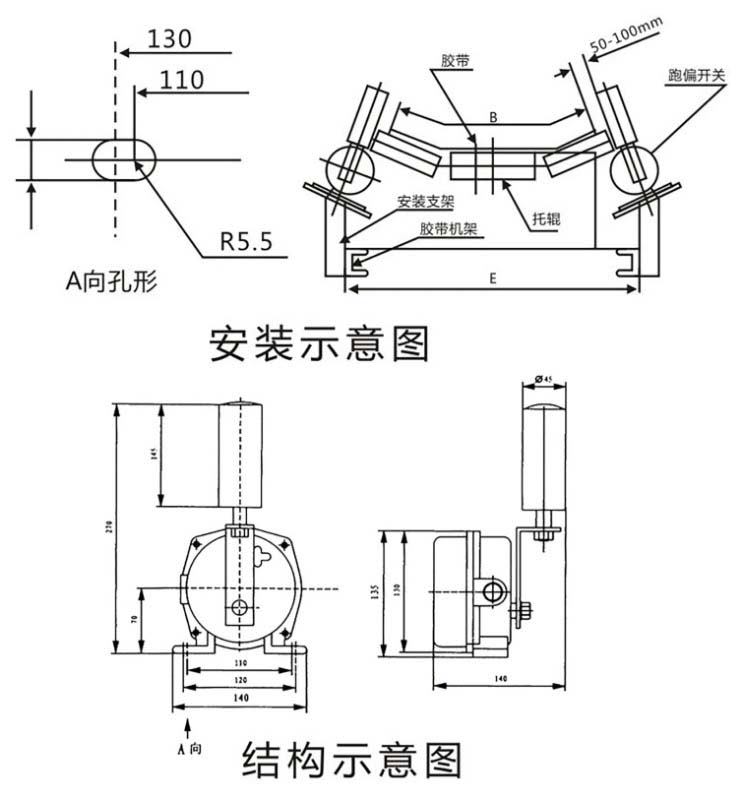

1. The gear wheel of the deviation switch is kept perpendicular to the belt< Br/>

2. It is recommended to maintain a distance of 120-160mm between the gear wheel of the deviation switch and the edge of the belt< Br/>

3. The base of the deviation switch is firmly fixed< Br/>

Installation instructions

1. Both sides of the base of the two-stage deviation switch have Ф 12mm hole, drilled on the iron frame next to the belt conveyor Ф 12mm hole, using M10× Tighten the deviation switch with 30mm screws< Br/>

2. The installation of the deviation switch should be carried out at a location where the conveying device is prone to deviation, referring to the process requirements of the application unit. At the same time, the distance and thrust between the belt and the blocking wheel should be considered. It is recommended to install the distance between the belt and the blocking wheel between 120-160mm< Br/>

3. Installation distance: It is recommended to install a pair of deviation switches every 50 meters< Br/>

4. The deviation switch is equipped with a 0.5 meter long four core rubber sleeve cable when leaving the factory. The core wire is equipped with wire numbers 1, 2, 3, and 4, where 1 and 2 are normally open contacts for warning signals and 3 and 4 are normally closed contacts for secondary shutdown signals< Br/>

&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)