RF admittance level meter

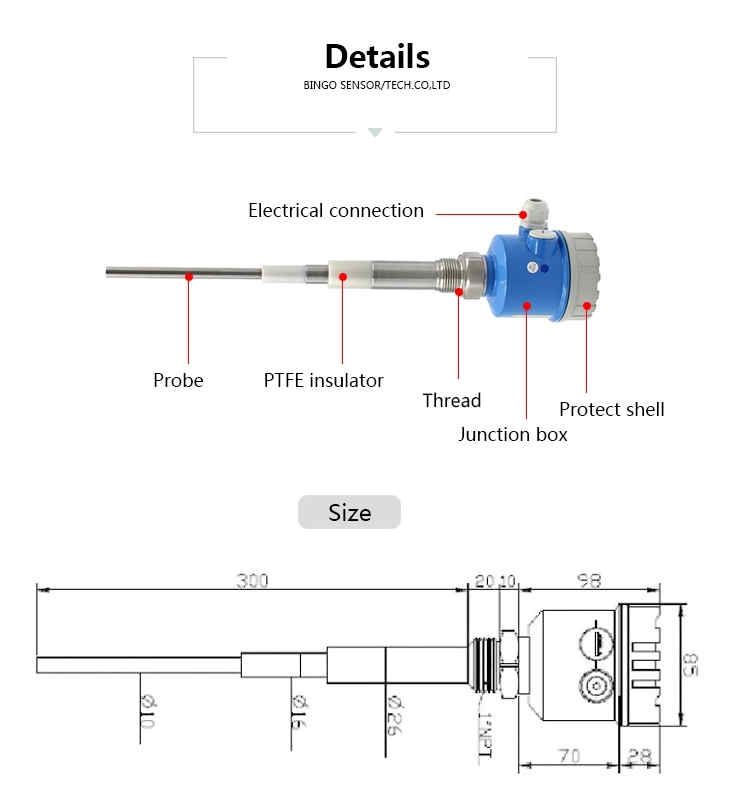

The radio frequency admittance level meter is composed of a sensor electronic unit, which mainly includes three parts: a measuring probe, a shielding electrode, and a grounding terminal. The height of the material is reflected by the change in admittance between the probe and the container wall. When the material reaches the switch operation point, the electronic unit responds, drives the relay, and outputs a switch signal.

- ZXRF series

- ZHUOXIN

- 24VDC

- IP67

- TT, PayPal, Credit card, Western union

- +86-15163766288

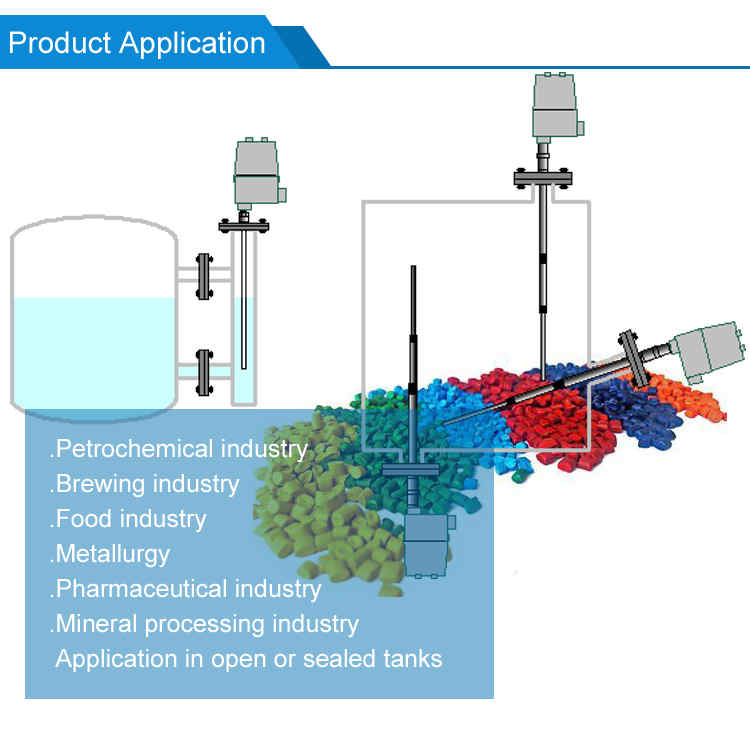

- The radio frequency admittance level meter adopts advanced radio frequency admittance technology, overcoming the defect that capacitive level switches cannot eliminate the influence of conductive hanging materials. The instrument operates reliably, and all technical indicators meet the international level of similar products. It is widely used for alarm and control of liquids, slurries, dust, material levels, and two types of liquid interface liquid levels. In addition, the product has added on-site working status indication, making it a very stable and reliable liquid level switch with a very high cost performance ratio.

Description

Working principle of radio frequency admittance level meter

The working principle of the radio frequency admittance level meter is based on radio frequency (RF) capacitor technology< Br/>

Apply radio frequency to the probe and determine the impact of the surrounding environment through continuous analysis. Because all materials have a dielectric constant and their conductivity is different from air, the total impedance reflected by the small capacitance offset will change when the probe comes into contact with the material. Due to the fact that the energized probe and the container wall form the two plates of the capacitor, the insulation of the probe and the surrounding air become dielectric materials. When air (with a dielectric constant of 1.0) is replaced by any other material (dielectric constant> 1), the capacitance effect is enhanced. Therefore, the impedance of the application has changed. That is to say, changes in capacitance value lead to changes in impedance. This effect is measured by the circuit and then compared with the reference frame established by the sensitivity setting (circuit). The correct setting of the sensitivity of the RF admittance level switch will affect the correct changes in the sensor output. The Nul1 KoTeTM circuit of the probe allows the measurement circuit to ignore material accumulation

Otherwise, it may cause sensitivity failure of the probe. The circuit is excited using the same RF potential as the RF potential applied to the sensing probe. Due to the inability of current to flow at the same potential, the circuit isolates the current that typically flows from the energized probe through the stacked material to the container wall. Measure the material around the energized probe in this way, rather than the stacked material< Br/>

Design characteristics of RF admittance level switches

1. Widely used: can be used for various conductive and non-conductive media, such as liquids, viscous materials, particles, powders, and fly ash< Br/>

2. Anti adhesion: The patented anti adhesion circuit eliminates false signals caused by material adhesion< Br/>

3. Detachable probe: There is no cable connection between the controller and the probe, so the controller can be disassembled and replaced at any time without affecting feeding or discharging< Br/>

4. High and low temperature resistance: suitable for working environments between -184 ℃ and 280 ℃, and can also provide ceramic probes at higher temperatures< Br/>

5. Output form: Double pole double throw relay signal output, with status lights displaying output status and a delay function of 0 to 30 seconds< Br/>

6. Non intelligent diagnosis: After power on, the instrument circuit automatically detects whether the working status is normal< Br/>

Application fields of RF admittance level switches

1. Casting machinery: detecting sand level< Br/>

2. Environmental water treatment: Detecting the water level of sewage< Br/>

3. Hydraulic machinery: detecting lubrication conditions

0

0&Nbsp;

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)