XZYE series Safety light curtain

Safety light curtains have emerged as a revolutionary technology that effectively protects employees and prevents accidents in high-risk environments. But how do they function, and why are they necessary? This guide will lead you on a tour of the inner workings of safety light curtains, illuminating their fundamental principles and highlighting their distinctive benefits.

- XZYE series

- ZHUOXIN

- 24VDC

- IP67

- TT, Paypal, Credit card, Western union

- +86-15163766288

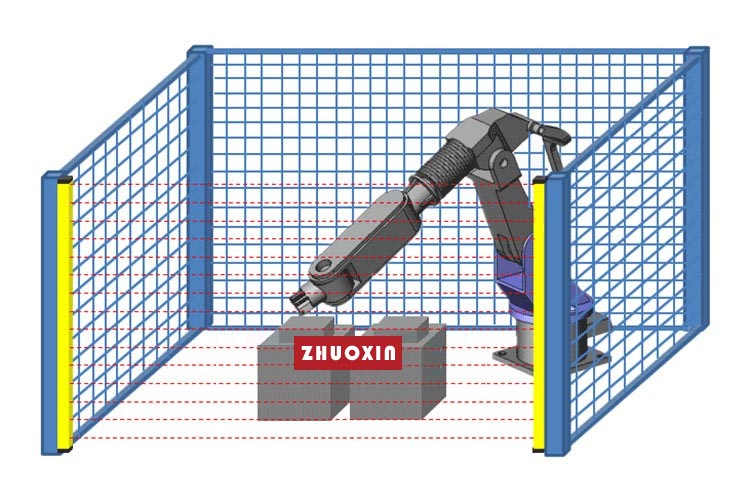

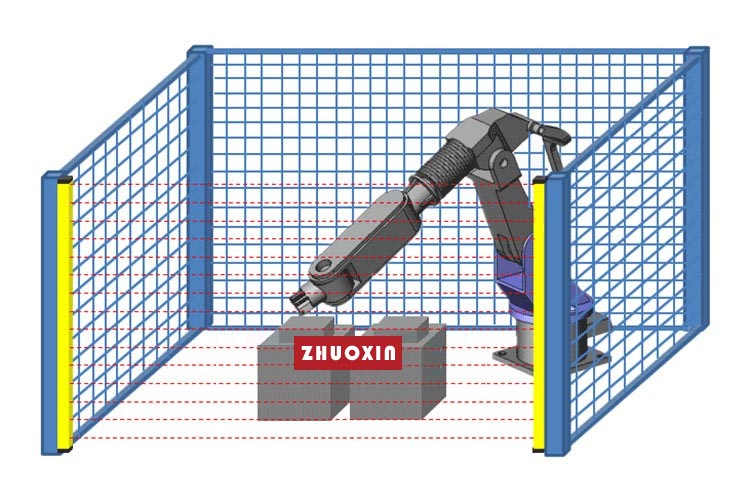

- A safety light curtain is an advanced safety device designed to safeguard personnel from harm and shield machinery from potential damage. This device utilizes one or more light beams, emitted by a transmitter, and received by a receiver, to create an invisible safety screen. The interruption of these light beams initiates a halt signal for dangerous, potentially hazardous processes, such as machinery operations.

Description

Safety light curtains have emerged as a revolutionary technology that effectively protects employees and prevents accidents in high-risk environments. But how do they function, and why are they necessary? This guide will lead you on a tour of the inner workings of safety light curtains, illuminating their fundamental principles and highlighting their distinctive benefits. We will go through the different types of available safety light curtains, their installation procedure, and how they can be integrated into your existing safety systems.

What Is a Safety light curtain?

A safety light curtain is an advanced safety device designed to safeguard personnel from harm and shield machinery from potential damage. This device utilizes one or more light beams, emitted by a transmitter, and received by a receiver, to create an invisible safety screen. The interruption of these light beams initiates a halt signal for dangerous, potentially hazardous processes, such as machinery operations.

The most straightforward function of a Safety light curtain occurs when light beams are obstructed, and the outputs turn off, signaling the cessation of the associated dangerous movement(s). A reset can be performed if there has been no incident and the area is secure.

How do safety light curtains work?

Recommence Interlock

Automatic and manual are the two most common interlocking modes that can be set. In an automated way, output signal-switching devices (OSSD) go high when the beams are unobstructed. The OSSDs go high in manual mode when the rays are free, followed by a manual reset signal activation.

Continuous Device Monitoring (EDM)

The level of safety performance for a safety function can be enhanced by implementing fault detection. ISO 13849 and ANSI B11.26, which are utilized to measure the safety performance of an SRP/CS, define the term diagnostics coverage (DC) to quantify this capacity. It is a measurement of the number of detected hazardous failures.

External Device Monitoring (EDM) or "check back" is a method that has a diagnostics coverage of 99.9% (can detect 99.9% of dangerous failures) and is extensively used in the industry.

This monitoring function allows a safety device to actively monitor the status of external devices, such as machine primary control elements (MPCEs), contactors, and relays. It is necessary because external devices typically lack diagnostics and are considered "dumb" devices.

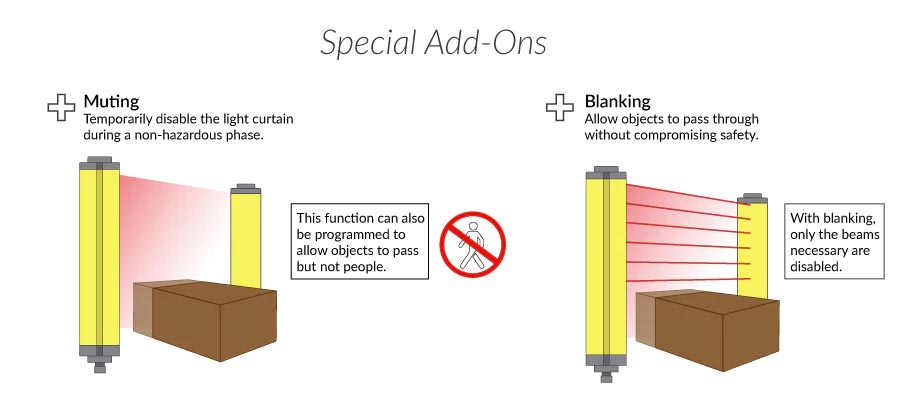

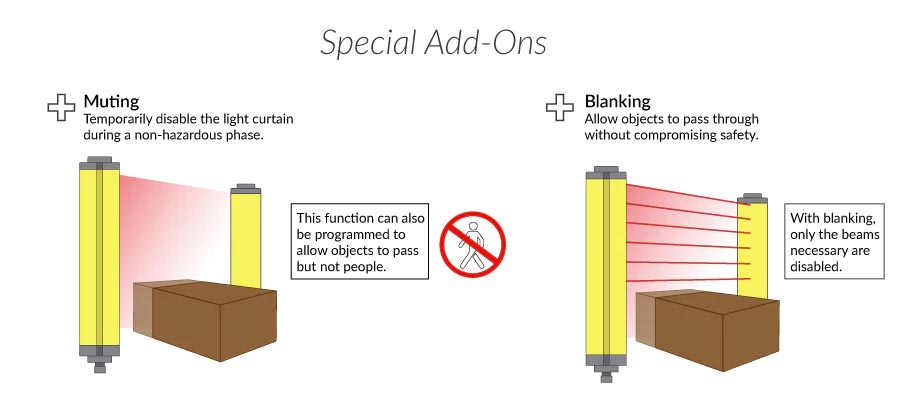

Blanking

In some applications, allowing specific objects to protrude through the light curtain field may be desirable without triggering an obstruction signal. For instance, when a support table or rack is required to input a heavy workpiece into the machine, a blanking feature can be used to modify the detection capability of the light curtain without interrupting the workflow.

Permitting Material Flow – Muting

In numerous applications, a Safety light curtain must permit the passage of objects while still sensing the presence of people. It is especially essential on conveying lines where goods move from one production area to another or in automated warehousing operations where employees are prohibited from the automatic stacking and shelving areas.

Sensors can identify the object (such as a vehicle body) and allow passage into a hazardous zone based on its size and shape while still detecting the presence of a person. It is automatic and is referred to as muted..

What Is a Safety light curtain?

A safety light curtain is an advanced safety device designed to safeguard personnel from harm and shield machinery from potential damage. This device utilizes one or more light beams, emitted by a transmitter, and received by a receiver, to create an invisible safety screen. The interruption of these light beams initiates a halt signal for dangerous, potentially hazardous processes, such as machinery operations.

The most straightforward function of a Safety light curtain occurs when light beams are obstructed, and the outputs turn off, signaling the cessation of the associated dangerous movement(s). A reset can be performed if there has been no incident and the area is secure.

How do safety light curtains work?

Recommence Interlock

Automatic and manual are the two most common interlocking modes that can be set. In an automated way, output signal-switching devices (OSSD) go high when the beams are unobstructed. The OSSDs go high in manual mode when the rays are free, followed by a manual reset signal activation.

Continuous Device Monitoring (EDM)

The level of safety performance for a safety function can be enhanced by implementing fault detection. ISO 13849 and ANSI B11.26, which are utilized to measure the safety performance of an SRP/CS, define the term diagnostics coverage (DC) to quantify this capacity. It is a measurement of the number of detected hazardous failures.

External Device Monitoring (EDM) or "check back" is a method that has a diagnostics coverage of 99.9% (can detect 99.9% of dangerous failures) and is extensively used in the industry.

This monitoring function allows a safety device to actively monitor the status of external devices, such as machine primary control elements (MPCEs), contactors, and relays. It is necessary because external devices typically lack diagnostics and are considered "dumb" devices.

Blanking

In some applications, allowing specific objects to protrude through the light curtain field may be desirable without triggering an obstruction signal. For instance, when a support table or rack is required to input a heavy workpiece into the machine, a blanking feature can be used to modify the detection capability of the light curtain without interrupting the workflow.

Permitting Material Flow – Muting

In numerous applications, a Safety light curtain must permit the passage of objects while still sensing the presence of people. It is especially essential on conveying lines where goods move from one production area to another or in automated warehousing operations where employees are prohibited from the automatic stacking and shelving areas.

Sensors can identify the object (such as a vehicle body) and allow passage into a hazardous zone based on its size and shape while still detecting the presence of a person. It is automatic and is referred to as muted..

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)